Double-suction pump

In double-suction pumps the total flow rate is distributed over several impellers arranged on a pump shaft. The head remains constant.

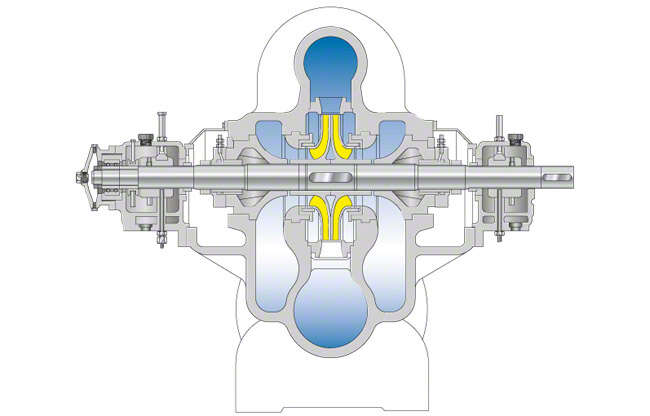

The most common type of multi-suction design in centrifugal pump engineering is a double-suction pump whose impeller pair is arranged back to back on the pump shaft (see Back-to-back impeller pump). This arrangement serves to balance the axial thrust. Due to this advantage and also due to their common pump suction nozzle and common volute casing double-suction pumps with back-to-back impeller arrangement can be compact in design, e.g. for use as water supply pumps. See Fig. 1 Double-suction pump

Fig. 1 Double-suction pump: single-stage, double-suction design with axially split casing

A double-suction pump with impellers arranged in parallel can be used to increase the flow rate at a constant head. Double-suction pumps are employed when the flow rate required of a centrifugal pump becomes too large for the inlet cross-sections of one impeller or when the flow velocity in the inlet cross-section of the first impeller has to be reduced to prevent cavitation.

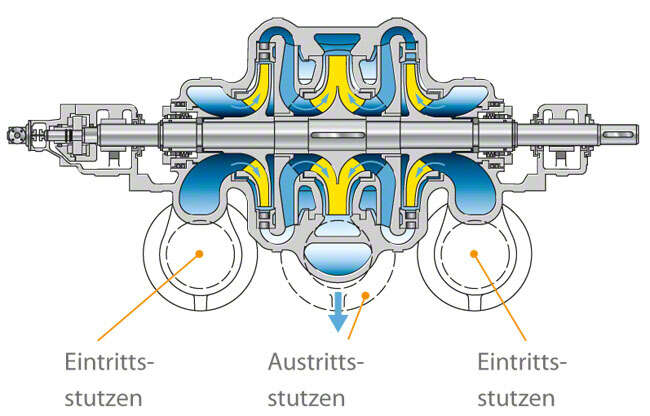

In principle, fourfold or sixfold suction designs are possible. However, as the branching and connecting elements required for such designs are very costly, they are used far less frequently than double-suction designs. See Fig. 18c Impeller

Double-suction or multi-suction pumps can also be designed with multiple stages, for example for use as pipeline pumps or large water supply pumps. See Fig. 2 Double-suction pump

Fig. 2 Double-suction pump: Two-stage, single-suction design with axially split casing