Circulating pump

Circulating pumps are centrifugal pumps designed to generate a forced circulation in a closed system. Examples are heating systems for hot water (see Circulator pump) or high-temperature hot water at temperatures above 120 °C (see Hot water pump), heat transfer systems (see Heat transfer pump), forced circulation boilers (see Fig. 3 Circulating pump) and reactor circuits (see Reactor pump). They are also used in open systems (e.g. swimming pool filtering systems). See Fig. 1 Circulating pump

The design of a circulating pump is often determined by the frequently high temperature of the fluid handled and the relatively low head (in relation to the system pressure), which corresponds to the head loss (see Pressure loss) in the circulation system. Different types of circulating pumps are used in closed pump circuits: circulating pumps with or without a shaft seal, and special designs.

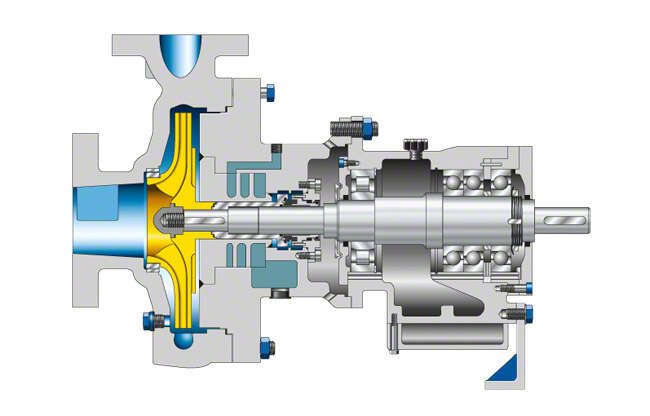

Circulating pump with shaft seal

Circulating pumps with a shaft seal are often horizontal pumps, driven by electric motors (see Drive) or steam turbines. Their pump shafts are sealed against the full pressure of the closed system by cooled gland packings or mechanical seals. The thrust bearing (see Rolling element bearing) has to be particularly robust to absorb the high static axial thrust.

See Fig. 2 Circulating pump

This type of pump is usually an economical solution for system pressures of up to 100 bar. For higher system pressures circulating pumps without shaft seal are used.

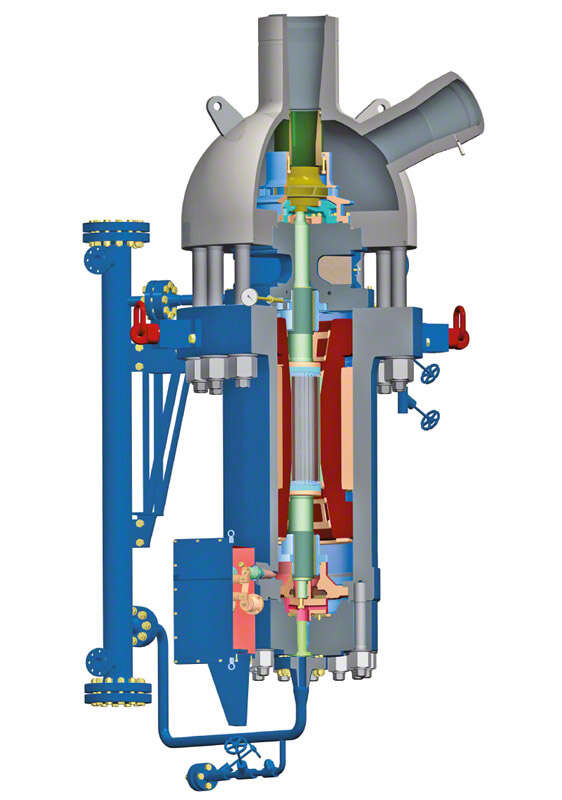

Circulating pump without shaft seal

Seal-less circulating pumps are also referred to as glandless circulating pumps. They are often vertical pumps, driven by wet rotor motors with or without a can (see Canned motor pump). See Fig. 3 Circulating pump

The pump and the electric motor are contained in a common, pressure-tight casing with a heat barrier between the pump section and the motor section. The heat barrier, which can either be an active or a passive component, enables the pump set to handle fluids with temperatures of up to 420 °C.

The bearings (see Plain bearing) are lubricated by the fluid handled. The system pressure is virtually unlimited. The completely leak-free design makes these pumps suitable for handling hazardous or valuable fluids.

Special designs of circulating pumps

Circulating pumps can also be specially designed for specific applications:

- With special impellers for liquid/gas mixtures or suspensions

- With sealing systems incorporating a gas cushion or meeting other special requirements of nuclear reactor technology

- With heating devices for liquids which solidify rapidly

- With protective lining preventing erosion

- Explosion-proof designs (see Explosion protection)

Fig. 1 Circulating pump: Self-priming circulating pump made of plastic, for swimming pool filtering systems

Fig. 2 Circulating pump: Horizontal pump with cooled shaft seal for forced-circulation boiler systems

Fig. 3 Circulating pump: Vertical pump, glandless circulating pump with wet rotor motor and heat barrier for steam power plants