Refinery pump

Refinery pumps transport petroleum and its derived products in refineries, petrochemical plants and the chemical industry. They are used in temperature ranges from -120 °C to +450 °C at pressures of about 65 bar.

As the fluids handled are often highly volatile and flammable, the pump components in contact with the fluid handled are always made of ductile materials such as unalloyed steel, chrome steel and, less frequently, also nodular cast iron.

The required NPSHR value is particularly important and governs the selection of the drive speed and type of pump.

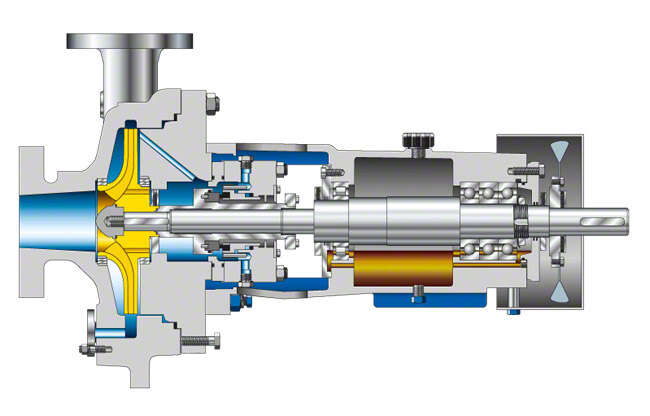

Refinery pumps are most commonly single-stage horizontal volute casing pumps in back pull-out design. See Fig. 1 Refinery pump

Fig. 1 Refinery pump: Horizontal model in back pull-out design

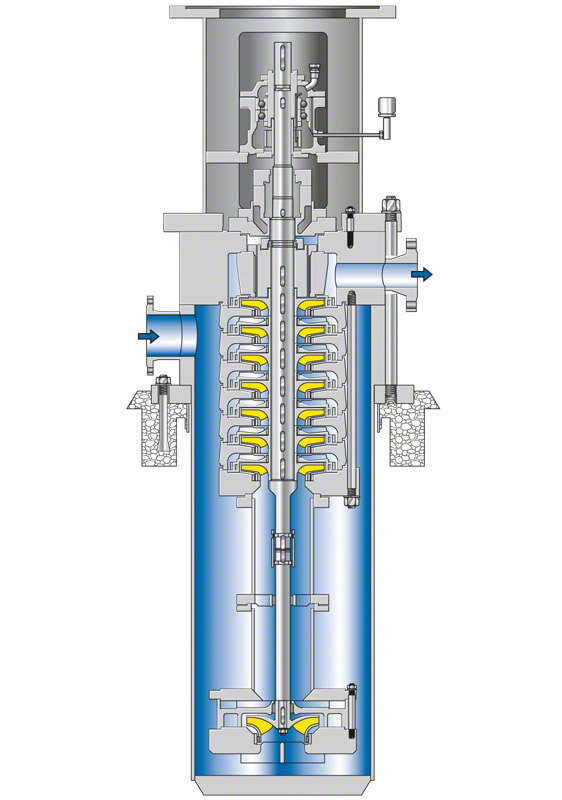

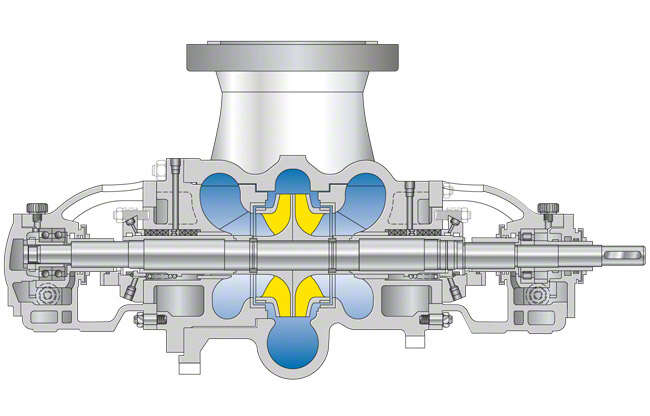

Depending on the operating conditions, particularly with regard to the suction characteristics refinery pumps can also be designed as horizontal or vertical can-typemultistage pumps or as horizontal double-suction pumps in between-bearings design. See Figs. 2, 3 Refinery pump

Fig. 2 Refinery pump: Vertical multistage refinery pump in can-type design, shown without shaft seal

Fig. 3 Refinery pump: Horizontal double-suction refinery pump

Refinery pumps have to comply with specific design codes, such as the well-known codes of the American Petroleum Institute (API 610) and the International Standards Organisation (ISO 13709). The codes which describe refinery pumps in greater detail refer to them as "heavy duty" pumps as they are generally suitable for heavy-duty operation.

They lay down certain design features applying to different operating temperatures, e.g. the arrangement of pump feet and nozzles, the mode of splitting the casing, the sealing elements and the temperature limits for cooling the bearings.

The shaft seals of refinery pumps are usually mechanical seals of various types and arrangements. The mechanical seals and their operating modes are described in API 682 or ISO 187498.

Great emphasis is placed on a sturdy and heavy construction as the piping is almost always hot and exerts considerable forces and moments on the refinery pump and its baseplate. These forces and moments must be absorbed safely without warping the pump or its baseplate (see Pump nozzle load).