Side channel pump

Side channel pumps share the characteristics of both positive displacement pumps and centrifugal pumps. In side channel pumps the power of a star-shaped impeller (e.g. star impeller) rotating concentrically in a casing is transferred to the fluid handled in a side channel arranged next to the impeller.

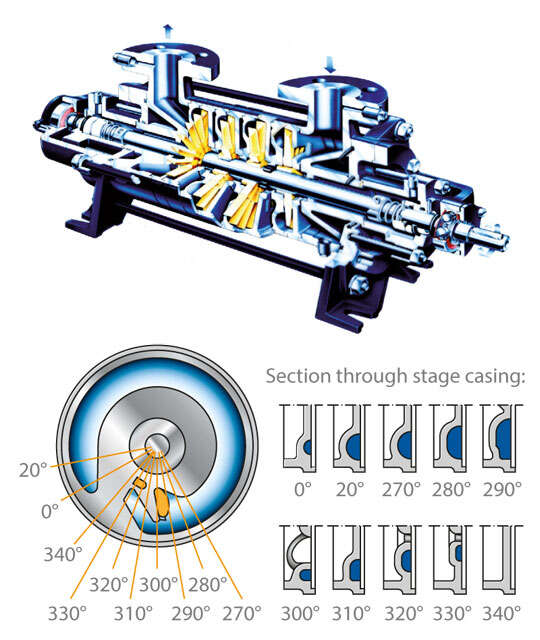

The star impeller is very simple in design. It has straight radial vanes and no impeller shrouds. Instead, the casing walls surround its circumference and its sides. Narrow clearance gaps are provided between impeller and casing. The casing is designed with a side channel on one side or with a side channel each on both sides. The side channel, which leads around the entire circumference, is interrupted in one point (between the inlet and the outlet slit). See Fig. 1 Side channel pump

Fig. 1 Side channel pump: Four-stage model; section through stage casing

When the impeller rotates, the fluid moves to and for several times between the cells of the star impeller and the side channel, which causes a strong transfer of energy by means of momentum exchange between the fluid rotating at almost the same high circumferential speed as the impeller and the fluid flowing slowly in the side channel.

This momentum exchange occurs repeatedly at the circumference and generates a very high head, which is 5 to 15 times as high as the heads generated by radial impellers of the same size rotating at the same circumferential speed.

Apart from high heads, which can be multiplied several times in case of multistage side channel pumps (see Multistage pumps), side channel pumps also have the advantage of being self-priming (see Self-priming pump).

Similar to the principle of water ring pumps the water remaining in the pump casing forms a water ring with a free surface when the star impeller rotates and air is sucked into the side channel pump through the pump suction nozzle.

This water ring would rotate concentrically and ineffectively in the casing if the side channel were not interrupted in one point of the circumference. The displacement action decreases the inner radius of the water ring in this part of the circumference. This also reduces the air-filled pockets between the radial vanes of the impeller. The side channel pump now operates as a compressor based on the principle of positive displacement, like a water ring pump.

Side channel pumps are used for applications which benefit from their self-priming capability and their high heads at low flow rates (compared to normal centrifugal pumps of the same dimensions). The only pumps exceeding the heads of side channel pumps are peripheral pumps.

Side channel pumps with a drive rating of more than 4 kW are rare because of their relatively low pump efficiency.