Cargo oil pump

Cargo oil pumps are installed on board tankers. Their duty is to pump the oil out of the vessel's tanks into land-based tanks at the port of destination. This process is supported by the pumps' stripping system. In addition, cargo oil pumps are often used as ballast water pumps to adjust the vessel's draught.

Cargo oil pumps are installed in the pump room, which is usually located in the stern of the vessel, between the tanks and the engine room. The pumps are installed as low as possible.

At the beginning of the pumping process the inlet head is relatively large. When the oil level has sunk to a very low level, the suction lift can be up to 5 m or higher. At this stage of the pumping process, air ingress through the suction nozzles into the suction lines is a frequent occurrence, as the suction nozzles are no longer fully immersed in the fluid pumped. Special air removal equipment is used to remove the air before it enters the pump.

Cargo oil pumps are driven by steam turbines, electric motors or Diesel engines. Their flow rate is adjusted by means of speed control (see Closed loop control). The connecting shaft between the engine room and the pump room is guided through a bulkhead with gland packing for safety reasons (fire and explosion protection).

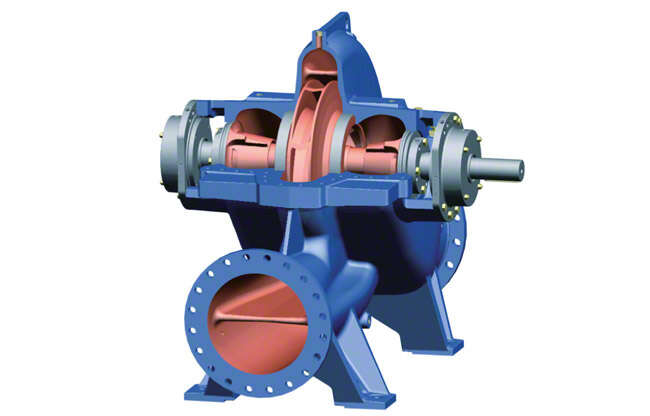

The pump casings are usually double volute casings made of cast copper alloy material. See Fig. 6 Volute casing pump

Depending on the size of the vessel the pump's flow rate ranges from 1,500 to 9,000 m3/h; its head averages 150 m. Apart from submersible pumps, which can only be used for small flow rates, double-suction pumps are generally employed because of their good suction capability at highest speeds.

For both horizontal pumps and vertical pumps axially split designs of the pump casing with double-entry impellers are preferable.

See Fig. 1 Cargo oil pump

See Fig. 1 Cargo oil pump

Fig. 1 Cargo oil pump: Horizontal axially split double-suction volute casing pump with radial impeller

Vertical pumps can also be required in single-entry, single-stage radially split design.

The sturdy oil or grease-lubricated rolling element bearings are arranged in close proximity to the casing. Sealing is effected by means of mechanical seals. Inducers are used if the NPSH values are low.