Cooling water pump

- Cooling with fresh water (see Wet cooling):

fossil-fuelled power station 100-120 m3/MW

nuclear power station 140-160 m3/MW - Indirect cooling with air (see Dry cooling):

fossil-fuelled power station 80-100 m3/MW

nuclear power station 120-140 m3/MW

- Range of head per impeller type

- Up to 10 m axial propellers are generally used (specific speed ns > 150 rpm)

- From 10 to 25 m mixed flow propellers can be used (100 rpm < ns < 150 rpm)

- From 10 to 40 m diagonal impellers (mixed flow impellers) are used (70 rpm < ns < 150 rpm)

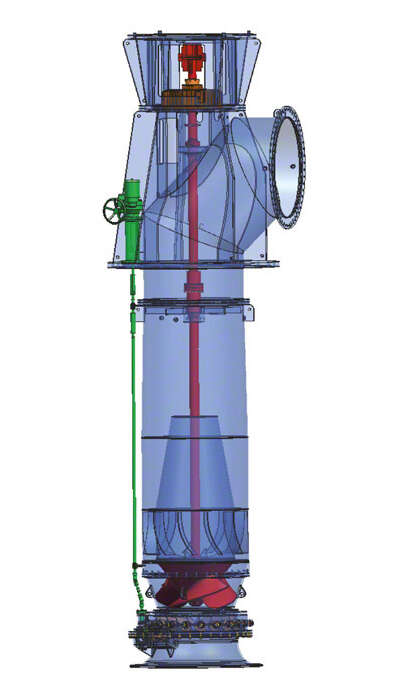

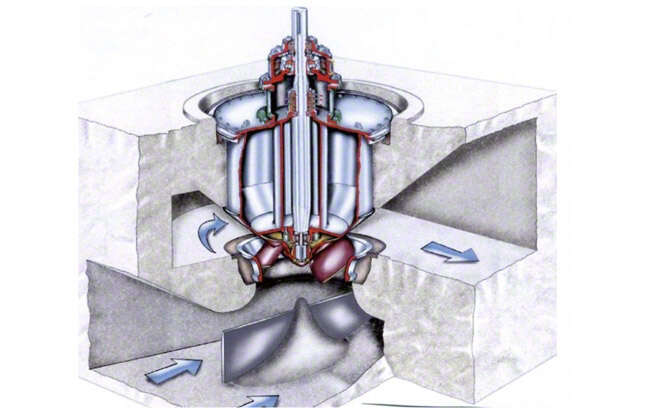

Fig. 1 Cooling water pump: Mixed flow pump with pre-swirl control equipment

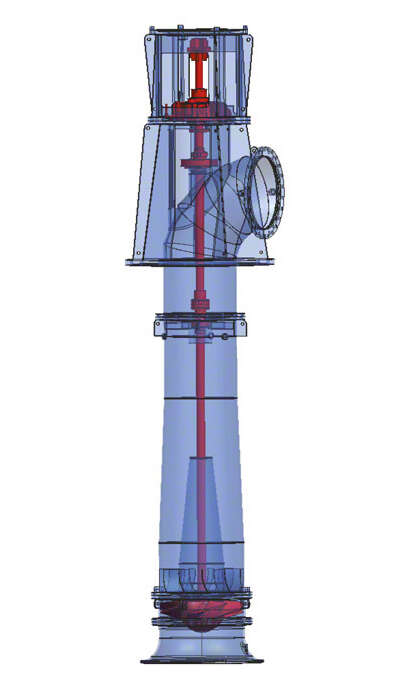

Fig. 2 Cooling water pump: Tubular casing pump with (adjustable) mixed flow propeller

Fig. 3 Cooling water pump: Tubular casing pump with (adjustable) axial propeller

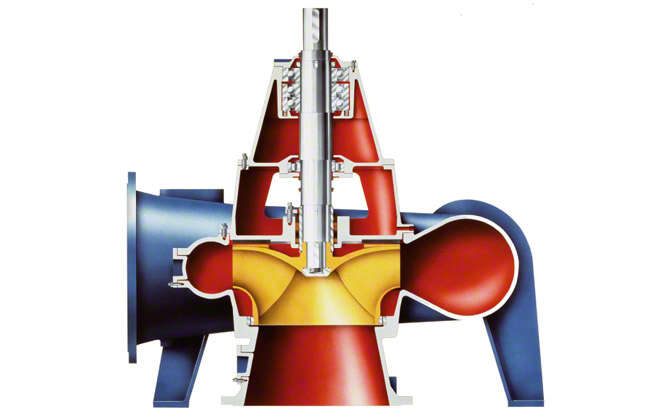

Fig. 4 Cooling water pump: Volute casing pump with mixed flow impeller

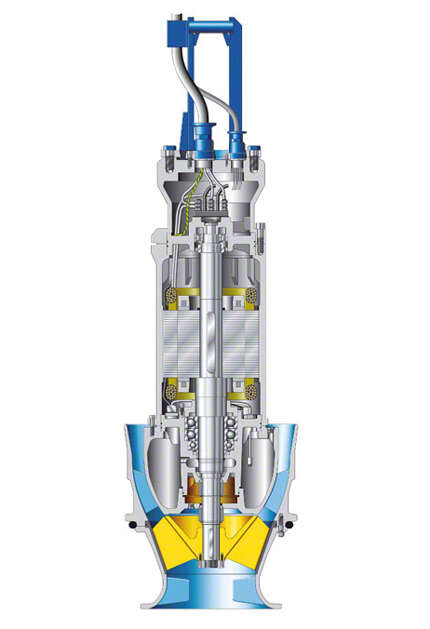

Fig. 5 Cooling water pump: Submersible motor pump with mixed flow impeller

Fig. 6 Cooling water pump: Concrete volute casing pump with mixed flow impeller

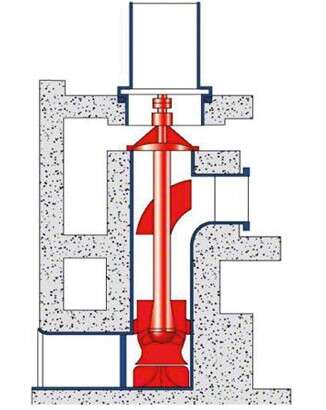

Fig. 7 Cooling water pump: Concrete tubular casing pump with adjustable mixed flow propeller (pull-out design)

- Mixed flow impeller See Fig. 1 Cooling water pump

- Mixed flow propeller See Fig. 2 Cooling water pump

- Axial flow propeller See Fig. 3 Cooling water pump

- Mixed flow propeller

- Mixed flow impeller, see Fig. 4 Cooling water pump

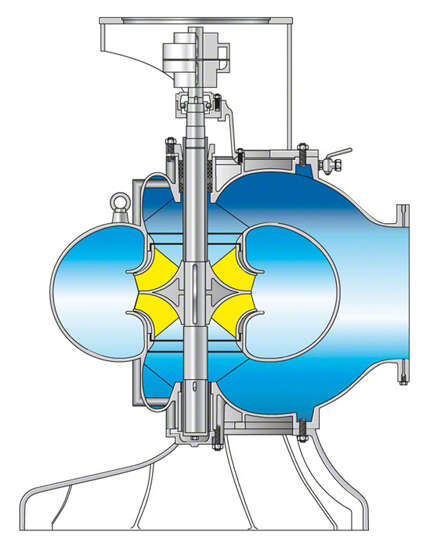

Fig. 8 Cooling water pump: Double-suction circular casing pump

- Adjusting the flow rate at constant head to the changing conditions in the heat exchanger (e.g. part load of the turbine)

- Adjusting the head at constant flow rate, if the pump head fluctuates with the water level on the suction side or if the operation changes over from fresh water to cooling tower operation

- If, after a pump failure, the remaining pumps are to pump 100 % of the cooling water flow

- Closing a throttling element (see Valve) in the discharge line (see Pump system) increases the head of the system and decreases the flow rate.

- There are limits to this type of control, as for specific speeds of ns > 100 rpm the pump power input increases with decreasing flow rate and may exceed the motor power available.

- In addition, the flow will separate from the vanes under specific low-flow conditions (see Operating behaviour) and the pumps will run rough (see Smooth running), which must definitely be avoided for continuous operation.

- Of the control methods described in this section, throttling generates the highest losses. Its use is generally confined to very small units. Throttling is not common in today's modern power stations.

- Speed control is used for adjusting the rotational speed of the pump. As a result, the head, flow rate and pump input power are adjusted in accordance with the affinity laws. However, the greater the static component (HS,0) of the system head (HS) (see System characteristic curve) the more the operating point deviates from its optimum at reduced speed. In other words, it shifts toward low-flow operation and, hence, toward the cut-off point. See Fig. 4 Closed-loop control

- Speed is either controlled directly or via a speed modulation gearbox. Three-phase motors are frequently selected as drives. Direct current motors are generally not suitable due to the large amounts of pump input power required for cooling water pumps.

- Lately, motors with frequency inverter have increased in popularity, also for larger ratings.

- Thyristors are used for electric speed control of three-phase motors with large ratings.

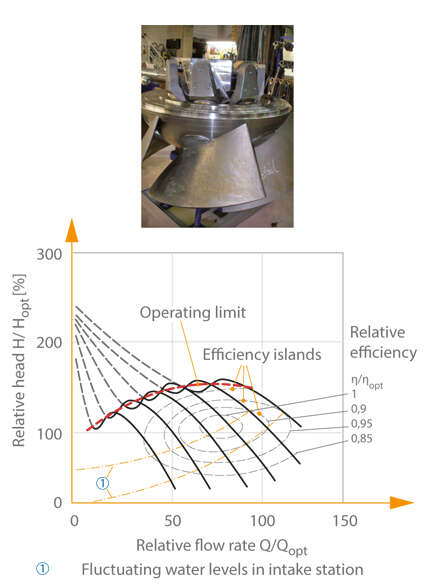

- This type of control is suitable for pumps with axial and mixed flow propellers. The impeller vanes are adjusted during pump operation.

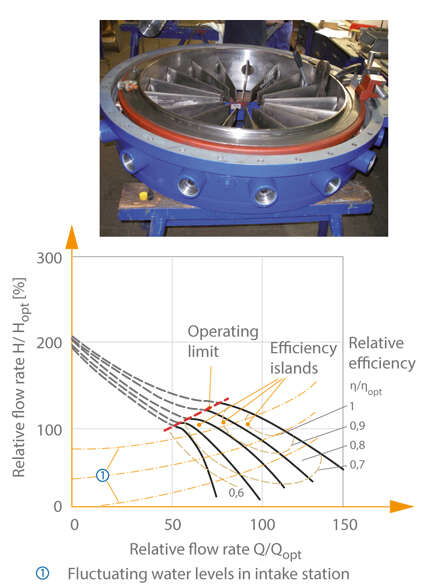

- The characteristic curves selection chart of such pumps with all possible adjustment angles generally shows elliptically shaped efficiency curves with almost horizontal

principal axes. See Fig. 9 Cooling water pump - This is the optimum type of control in cases where large changes in flow rate at relatively small variations in head and an almost constant efficiency are required.

Fig. 9 Cooling water pump: Typical characteristic curves selection chart of a propeller pump controlled by axial or mixed flow impeller blade pitch adjustment (Top figure: Propeller head with blade pitch control equipment)

- This type of control is used for pumps with mixed flow impeller. The flow upstream of the impeller is influenced by imparting pre-swirl. The flow rate is increased by inducing pre-swirl in the same direction as the impeller rotation or decreased by inducing pre-swirl in the opposite direction. This is effected by a stationary vane cascade with adjustable pitch angle, fitted upstream of the impeller. See Fig. 1 Cooling water pump

- The selection chart of such pumps with all possible pre-swirl angles generally shows elliptically shaped efficiency curves. The principal axes run (roughly) parallel to the pump characteristic curve. They differ in this respect from the ellipses of impeller blade pitch control, whose principal axes run almost horizontally. See Fig. 10 Cooling water pump

- This is the preferred type of control in cases where relatively small changes in flow rate at large variations in heads and optimum pump efficiencies are required.

Fig. 10 Cooling water pump: Typical characteristic curves selection chart of a pre-swirl controlled mixed flow pump (Top figure: Pre-swirl control equipment for a cooling water pump)