Warm Congratulations to the Successful Hosting of the First-Batch Delivery Ceremony for BASF Zhanjiang Integrated Project

BASF Zhanjiang integrated base, the largest investment of BASF overseas project, was first announced for construction in July 2018 and officially launched in November 2019, and the total investment will reach 10 billion Euro by 2030. Independently constructed and operated by BASF, once completion, the project will be the third largest integrated production base of BASF in the world after Ludwigshafen, Germany, and Antwerp base, Belgium.

The new integrated base will include a steam cracking unit of 1,000,000 tons of Ethylene per year and several manufacturing units of downstream products for the consumer market. By adopting cutting-edge technologies, full smart production concept and the highest safety standard, the base will be a model of intelligent and sustainable manufacturing. The entire base is expected to be completed in the year of 2030.

Since the second half of 2022, KSB Shanghai Pump Co., Ltd. has quoted for more than 50 inquiry packages on 9 clusters and received orders for nearly 300 centrifugal pumps, amounting to RMB 100million RMB , the largest-ever order between KSB and BASF.

KSB has made two major ground-breaking achievements in this project:

1. EOEG application. In the process where naphtha is cracked into ethylene, the highly flammable EO explodes easily if exposed to the air so that the leakage is strictly forbidden. Therefore, the requirement for stability operation for our pump is very harsh. For this mainstream application, KSB obtained the orders for 20 sets of RPH (OH2) and 2 sets of RPHb (BB2).

2. Two orders of turbine-driven pumps for RDL & OMEGA and each order is over 10 million RMB.

KSB has made two major ground-breaking achievements in this project:

1. EOEG application. In the process where naphtha is cracked into ethylene, the highly flammable EO explodes easily if exposed to the air so that the leakage is strictly forbidden. Therefore, the requirement for stability operation for our pump is very harsh. For this mainstream application, KSB obtained the orders for 20 sets of RPH (OH2) and 2 sets of RPHb (BB2).

2. Two orders of turbine-driven pumps for RDL & OMEGA and each order is over 10 million RMB.

To ensure the customer's supreme safety standard and the design requirements of intelligent and sustainable manufacturing, KSB mobilized the best technical staffs, redid the calculation and analysis from the design stage, worked out a series of new manufacturing processes and developed new production mode and digital delivery system, thus laying a firm foundation for the high-quality delivery of the pump equipment as scheduled.

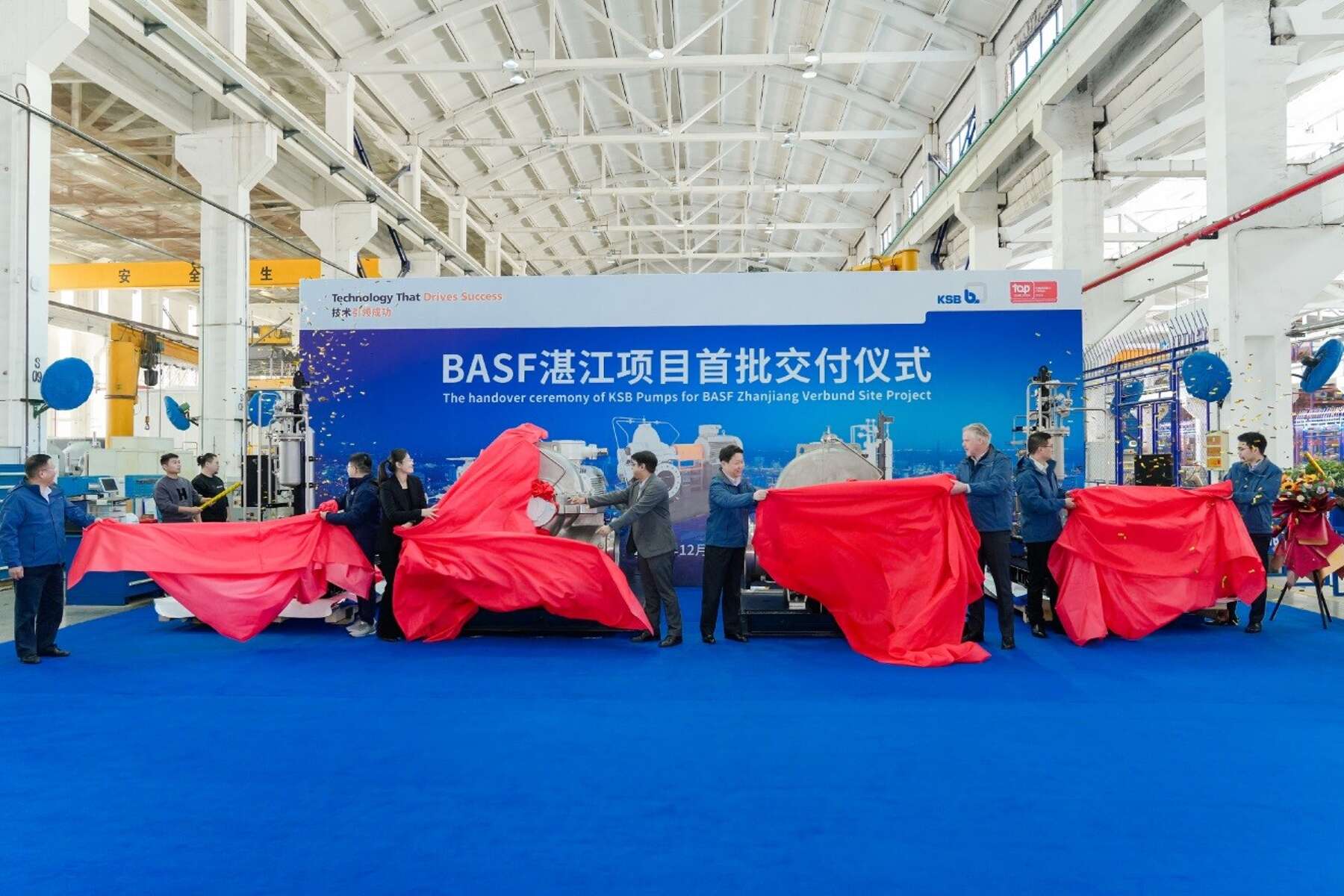

After the successful performance acceptance tests and the final customer acceptance, KSB Shanghai Pump Co., Ltd. will deliver 21 centrifugal pumps, including RPH, OMEGA, MCKP, and ETN, for the EOEG Application in December 2023.

Upon the witness of BASF and KSB colleagues, the first-batch delivery ceremony for BASF Zhanjiang integrated project was successfully hosted in KSB Shanghai Pump Co., Ltd. Jiangchuan Road factory.

During the ceremony, the managers reiterated the importance of BASF project to KSB and wished more glories and success to BASF project.

During the ceremony, the managers reiterated the importance of BASF project to KSB and wished more glories and success to BASF project.