Efficiency scale-up

Efficiency scale-up takes account of the influence of the Reynolds number (Re number) on the pump's efficiency. When two geometrically similar centrifugal pumps are compared, either the larger one, the one with the higher speed or the one handling a fluid of lower viscosity usually exhibits a higher pump efficiency. This means that when transferring data established on a test model to a life-size prototype, the pump efficiency measured on the model must be scaled up. The pre-condition is however that geometrical similarity has been maintained in all components including surface roughness and clearance gap width (see Similarity conditions).

Thus this change in efficiency is only a consequence of the change in the Reynolds number resulting from the change in pump size, rotational speed and viscosity.

Larger centrifugal pumps generally have higher Re numbers. According to the laws of fluid mechanics, these pumps exhibit lower flow losses within certain limits and therefore feature a higher internal efficiency.

As it is almost impossible to achieve exact geometrical similarity, it is important to take into account that the additional influence of the machine size has the same effect as that of the Re number. The influence of pump size on pump efficiency is of practical significance in all cases where efficiency measurements are performed on reduced scale models of larger pumps (see Pump test facility). This allows an evaluation of the anticipated efficiency of the life-size pump to obtain the pump input power, for instance, which would have exceeded the installed test facility power.

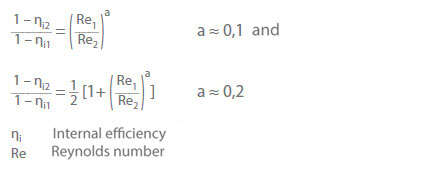

There are as yet no universally applicable rules for efficiency scale-up. In all cases, the efficiency scale-up method used must be clearly defined between user and manufacturer before the model test takes place. Examples of approximation equations for efficiency scale-up are those given by Pfleidererand Ackeret:

The Re number should be calculated on the basis of the circumferential speed of the impeller outlet diameter.

Practical examples for the use of efficiency scale-up equations are found in international standards: "Hydraulic Institute: Standards for centrifugal, rotary and reciprocating pumps. 14th ed, Cleveland 1983" and "IEC 497: International code for model acceptance tests of storage pumps. 1976" (12/2011 edition).