Fire-fighting pump

A fire-fighting pump is a centrifugal pump which is used for pumping fire-fighting water. Fire-fighting pumps can be designed for transportable use (e.g. on fire-fighting vehicles or as portable fire pumps) or for stationary use (e.g. hydrants, sprinkler systems).

Transportable fire-fighting pump

Transportable fire-fighting pumps are single-stage or multistage single-entry centrifugal pumps. Transportable fire-fighting pumps are self-priming (see Self-priming pump). They are of compact, light-weight design. See Fig. 1 Fire-fighting pump

Fig. 1 Fire-fighting pump: Mobile fire-fighting pump (portable fire pump with water ring pump for venting)

The sizes and operating data of fire-fighting pumps are standardised to EN 1147, EN 14466 and EN 1028-1; the corresponding suction and discharge hoses are standardised to DIN 14810, and the couplings to DIN 14811. The pressure losses in the hoses correspond approximately to the pipe friction losses in plastic piping.

The drive is usually a combustion engine, allowing the speed to be simply controlled via the fuel supply. In practice, the flow rates and heads can vary widely (see Throw).

The drive is usually a combustion engine, allowing the speed to be simply controlled via the fuel supply. In practice, the flow rates and heads can vary widely (see Throw).

Transportable fire-fighting pumps are either installed on fire-fighting vehicles as integrated or front-mounted pumps, or they are used as portable fire pumps. Portable fire pumps consist of a pump end flanged to a motor. This assembly is mounted on a protective frame. Some modern portable fire pumps (which exceed the standards in size) are driven by a gas turbine, which not only allows universal fuel selection but also increases the output and decreases the weight. For weight reasons the protective frame often consists of two separate parts, which allows the pump end to be quickly and easily separated from the drive end. Pumps which are mounted on fire-fighting vehicles are driven by the vehicle's motor via a jackshaft.

The following systems are used for venting (see Self-priming pump):

- Water ring pump, continuously running on a common shaft with the fire-fighting pump

- Oil ring pump installed next to the fire-fighting pump, driven by the shaft of the fire-fighting pump via a friction wheel during the venting process

- Eductor (see Eductor-jet pump) using part of the exhaust gas of the combustion engine or compressed air of the compression stage of the gas turbine

- Manual air pump

Fire-fighting pumps are usually single-stage volute casing pumps, double-suction radial flow pumps (see Double-suction pump), ring-section pumps, submersible borehole pumps and deep-well turbine pumps. They extract fire-fighting water from tanks, fire water ponds, rivers or lakes.

Fire-fighting pumps are usually in idle state. They are only operated for testing water / water mist systems (to PREN 14972) or foam systems (to EN 13565), and in the event of fire. This is why reliable start-up and fast ramp-up to full pump power output (also after prolonged standstill) is of particular importance.

Applicable regulations are issued by fire insurance companies and associations such as VdS Schadensverhütung, Factory Mutual, National Fire Protection Association, APSAD/CNPP and LPCB.

Stationary fire-fighting pump

The most important and most common fire-fighting systems are sprinkler systems. Sprinkler systems consist of several sprinkler heads which are connected via a piping system. Large heat automatically triggers the sprinkler heads in defined intervals to protect the rooms they are installed in. Sprinkler systems are automatic fire-fighting systems.

Fire hydrants are another type of fire-fighting system. Hydrants are activated manually. Depending on their type they are either designed for general use or for activation by fire-fighters only.

Wet-pipe sprinkler systems are the most common type of sprinkler system. In this system, the pipelines are permanently under pressure and filled with water. The fire-fighting water will be discharged immediately as soon as one or several sprinklers have been activated.

In dry-pipe sprinkler systems pipelines laid in areas which are likely to be effected by frost/freezing are filled with air.

In dry-pipe sprinkler systems pipelines laid in areas which are likely to be effected by frost/freezing are filled with air.

Depending on the hazard class, sprinkler systems may be required to be supplied with water from two independent sources, using either one or two fire-fighting pumps. If two pumps are used, two independent energy sources may have to be provided, depending on the applicable regulations.

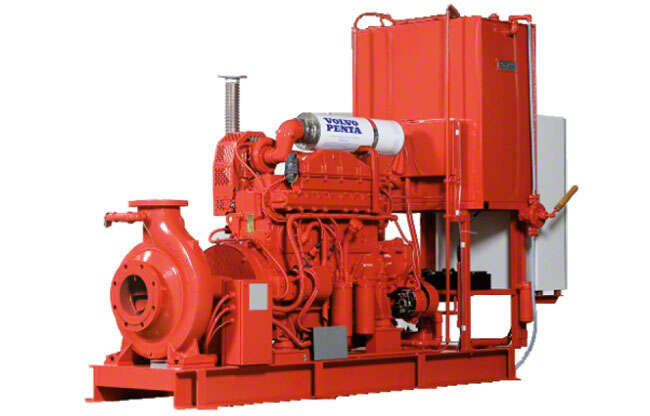

Fire-fighting pumps can be driven by an electric motor or a combustion engine. See Fig. 2 Fire-fighting pump

Fig. 2 Fire-fighting pump: Stationary unit with combustion engine

To ensure that stationary fire-fighting pumps start up reliably for testing the fire-fighting system or in the event of fire, stationary fire-fighting pumps are designed in compliance with the relevant regulations such as VDS CEA 4100 and subjected to a type test by an independent certifier.