KSB - one of the world's leading manufacturers of industrial valves and pumps

Founded in 1871 in Frankenthal (Germany), KSB has been one of the leading suppliers of pumps and industrial valves for over 150 years. With more than 16.000 employees worldwide and its own sales and marketing, manufacturing facilities and service operations, KSB develops and produces custom-fit pumps for various applications.

As an experienced pump manufacturer, its product portfolio includes building and industrial technology, water transport, wastewater treatment and power plant processes. Thanks to innovative research and development, KSB can meet the most diverse requirements of customers. Benefit from many years of experience and technical expertise as a renowned pump manufacturer.

KSB pump manufacturers: the best solution for your plant

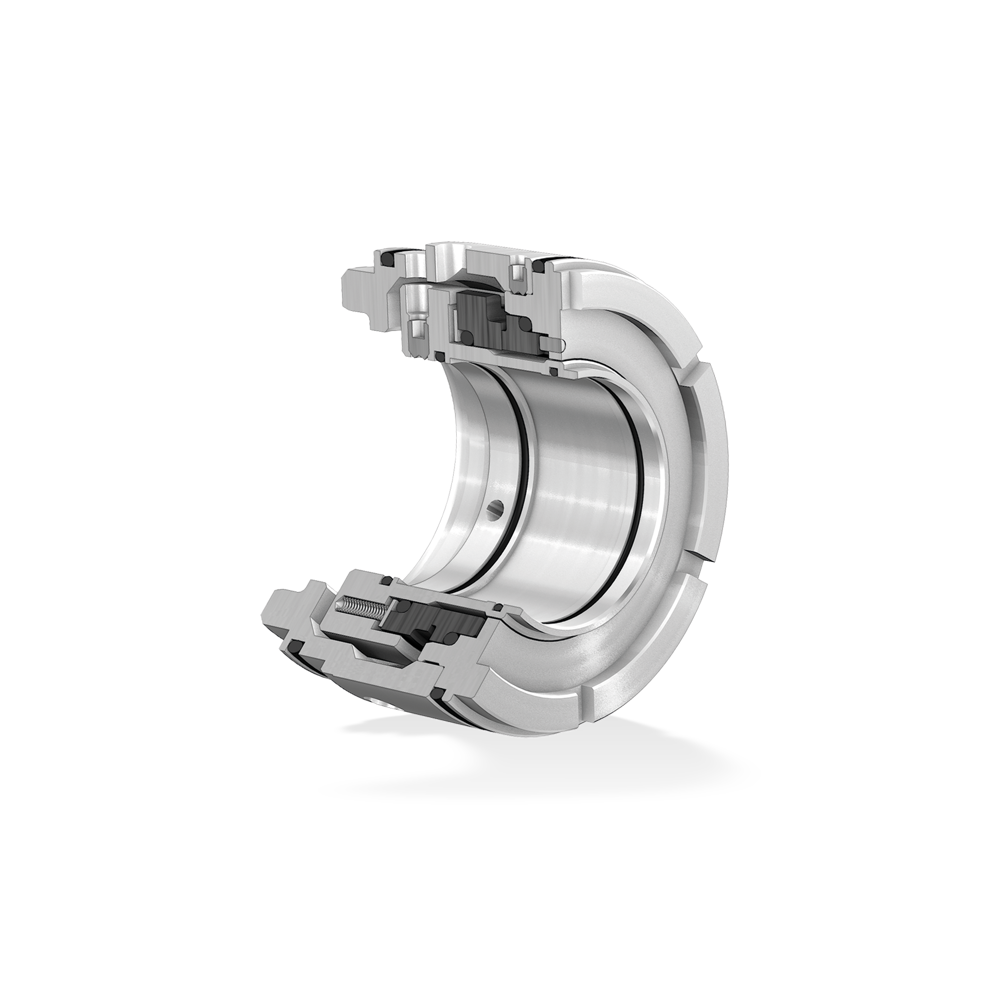

Industrial pumps and valves from KSB cover a wide range of applications and are highly energy-efficient. Products convince with the most innovative technology as well as with systems that have been tried and tested for many years - including the Etanorm water pump. Achieving more than 1.5 million sales worldwide, Etanorm is the most successful standard water pump. With KSB spare parts and services.

KSB ensures the operational reliability of its industrial pumps and valves. The KSB success formula for high-performance pumps lies in the technological strength in hydraulics, materials and automation.

Competent service right from the start

The numerous production facilities ensure that KSB as a pump manufacturer can guarantee customer proximity and first-class service. The experienced specialists are certified to ensure excellent quality and extensive experience. KSB Service takes care of the commissioning, inspection, servicing and maintenance of your pumps, valves and complete systems directly on site. KSB also provide you with spare parts quickly. This means you get the best service directly from your pump manufacturer.