Spare parts: A sophisticated system is behind every fast delivery

If a pump component fails, the downtime costs for the company start to increase rapidly. KSB supplies the right spare part quickly and smoothly – whether it’s a joint ring weighing just a few grammes or a casing for a mining pump weighing several tonnes. But behind this seemingly run-of-the-mill process is a global logistics system that guarantees efficiency and reliability.

Four factors for efficient spare parts logistics

Whether via the KSB Web-Shop, the MyKSB customer portal, an electronic interface from the company’s own SAP system or in the traditional way via a sales or service employee, ordering spare parts is easy for KSB customers. However, it takes a combination of experience, technology and foresight to ensure that the components reach our customers quickly and reliably. Here are four factors that are crucial to ensuring fast spare parts deliveries:

2. A worldwide network of warehouses

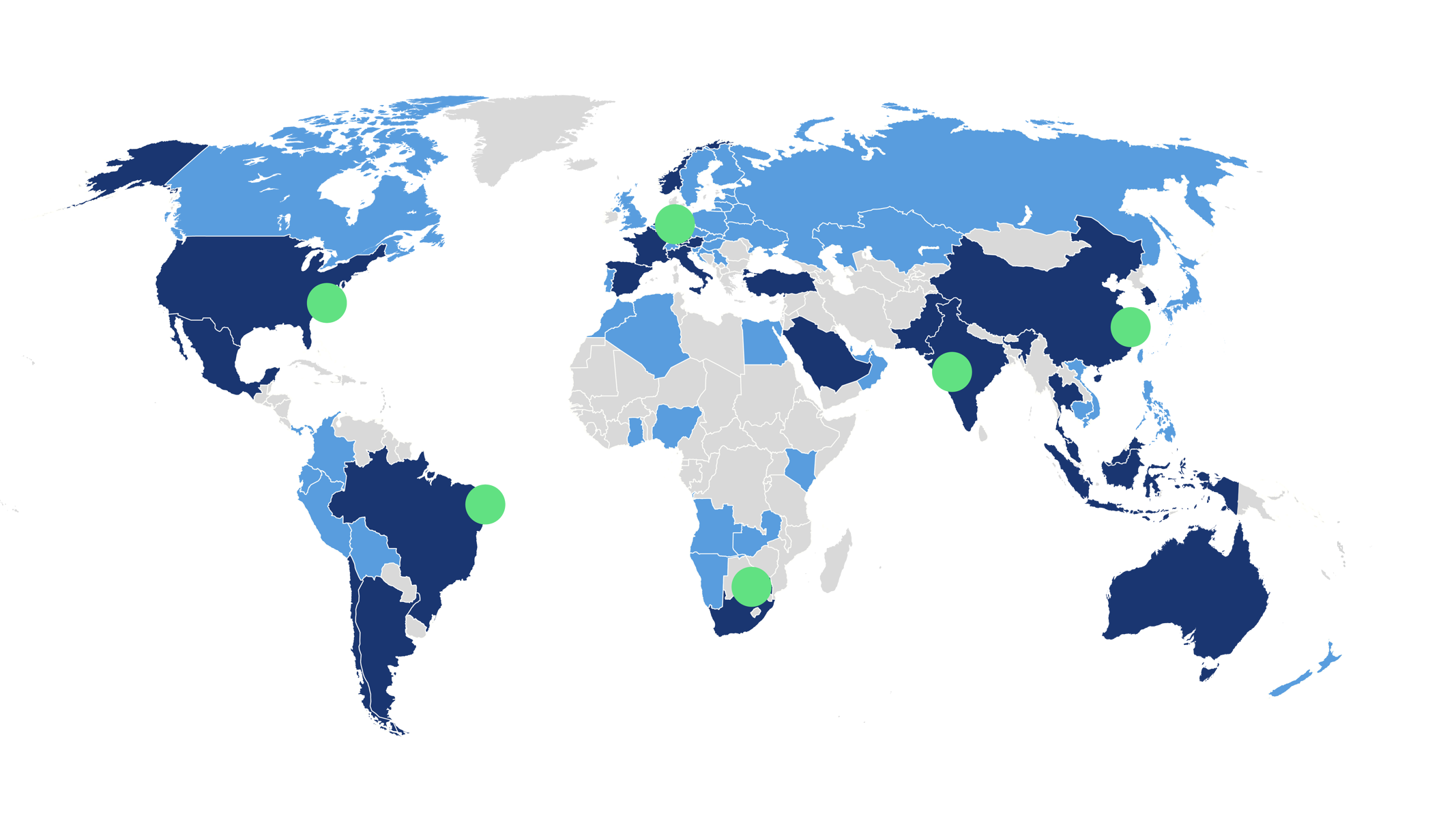

With a global network of six spare parts warehouses in Grünstadt (Germany), Johannesburg (South Africa), Pune (India), Shanghai (China), Várzea Paulista (Brazil) and Richmond (USA), KSB ensures that spare parts reach customers quickly and efficiently. This network offers two advantages: Firstly, the locations around the globe shorten transport routes, which significantly reduces delivery times. Secondly, the warehouse contents are precisely tailored to the needs of the local markets.

For example, while spare parts for water pumps play a major role in Europe, spare parts for mining pumps are very important in South Africa. The global network of warehouses enables KSB to keep exactly the parts that are needed in stock in every region. Global networking via SAP enables transparent and efficient management. As the warehouses are digitally linked to each other, it is immediately clear which parts are available in India, China or South Africa. If a spare part is not in stock at one location, it can be quickly ordered from another warehouse. Following the principle of “local for local”, the strategic positioning of the warehouses close to the production plants ensures that most spare parts are manufactured locally. This not only saves time, but also enables additional services such as impeller trimming to adjust the flow rate of centrifugal pumps to match the optimum operating point.

4. The right logistics partner for every order

Fast and reliable delivery of spare parts depends on selecting the right logistics service provider – and KSB leverages the full spectrum of the logistics industry. Whether air freight, sea freight, DHL, GLS, FedEx or Schenker, every order is processed using the most suitable service provider. This ensures that both a small seal in an envelope and a component weighing several hundred kilograms will reach the customer quickly and efficiently.

KSB’s global network of spare parts warehouses is once again an advantage here. The local employees are familiar with all the logistics service providers and know which provider is best suited to a particular order. Local logistics partners often have a particularly well-established network in their region, which further shortens delivery times. Where possible, KSB is networked with service providers via IT connections. This speeds up the ordering process and enables seamless delivery status tracking in real time. Thanks to a global warehouse network combined with targeted selection of logistics service providers and digital networking, KSB ensures that spare parts are delivered quickly, reliably and accurately – all over the world.