Parallel operation

Parallel operation, or parallel pumping, of two centrifugal pumps is a mode which allows pump operation to be controlled by starting or stopping one of the two pumps.

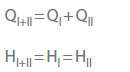

If two centrifugal pumps I and II are operated in parallel, the flow rate QI+II is the sum of the flow rates of the individual pumps at the same head, i.e.:

The actual flow rate and head of pumps operating in parallel (operating point) is the intersection of the common pump and system characteristic curves. See Fig. 1 to 5 Parallel operation

Each pump must be secured with its own check valve (see Valve). Centrifugal pumps run in parallel will operate without any problems if theirn characteristic curves are stable and both have the same or almost the same shut-off head. See Fig. 1 Parallel operation

Fig. 1 Parallel operation: Two centrifugal pumps I and II with stable characteristic curves

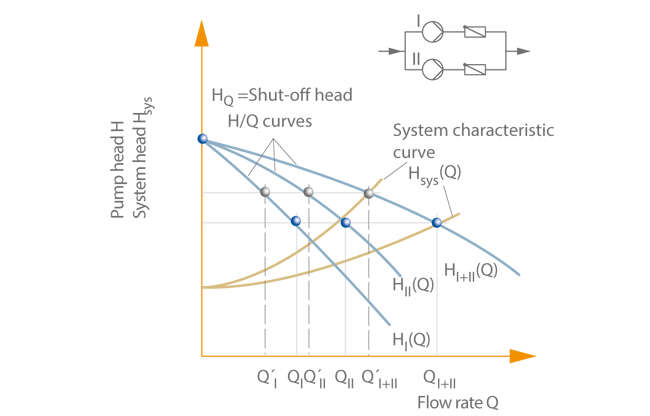

Trouble-free operation does not necessarily require that the pumps exhibit the same characteristic curves (H/Q). When QI+II decreases to Q´I+II, then the individual flow rates QI and QII also decrease to Q´I and Q´II. If the shut-off heads (H0) of pumps I and II are different, pump I is rapidly pushed towards the shut-off point while pump II continues pumping. See Fig. 2 Parallel operation

Fig. 2 Parallel operation: Two centrifugal pumps I and II with different shut-off heads

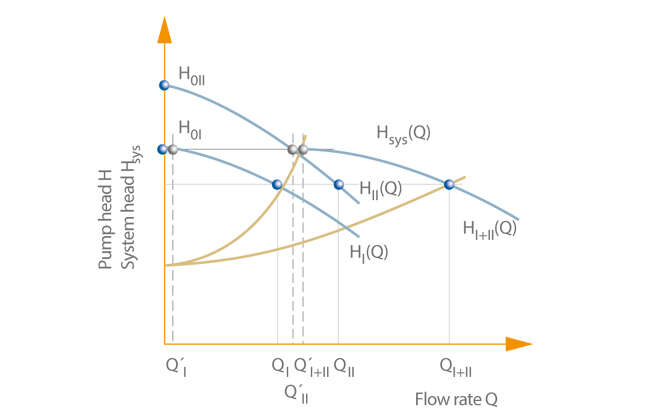

In the case of two centrifugal pumps I and II with unstable characteristic curves and the same peak heads (Hpeak), parallel operation is possible in the range 4 to 5 where any further pump of the same characteristics can cut in without any problems. See Fig. 3 Parallel operation

Fig. 3 Parallel operation: Two centrifugal pumps I and II with unstable characteristic curves and the same peak heads

At point 4, one other pump of the same characteristics can be started due to the shut-off head (H0). Between points 4, 3, 2 and 1 down to almost 0, this is no longer possible. In these operating ranges the pump, whose shut-off head (H0) is smaller than HI+II, would not be able to open the check valve because of the pressure exerted on it by the other pumps.

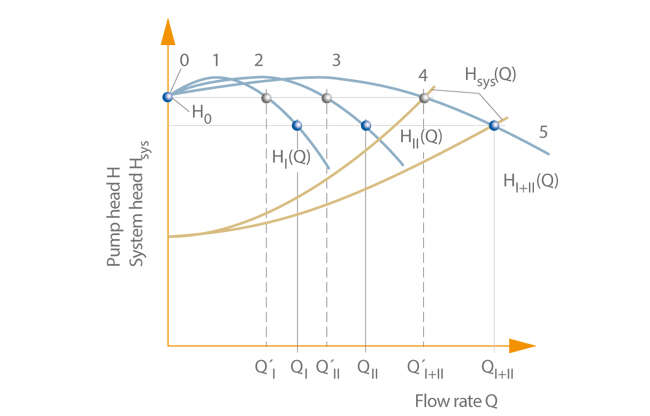

A further example of pumps in parallel operation shows two centrifugal pumps I and II with unstable characteristic curves where the peak head (Hpeak) of pump I is higher than that of pump II. As soon as the head at the operating point (HI+II) is higher than the smallest value of the peak head (HpeakII) parallel operation will lead to a very complex transient flow pattern. When starting parallel centrifugal pumps with unstable characteristic curves and different shut-off heads, the pump with the smaller shut-off head (H0II) will not be able to open its check valve against the pressure of the other pump (H0I > H0II) and must therefore be started first.

See Fig. 4 Parallel operation

See Fig. 4 Parallel operation

Fig. 4 Parallel operation: Two centrifugal pumps I and II with unstable characteristic curves and different peak heads

This type of constraint can lead to interruptions in pump operation and should be eliminated by meticulous planning right from the start.

If parallel operation of two pumps is not specified, it is easier and less costly to design a double-suction pump instead of using two separate centrifugal pumps.

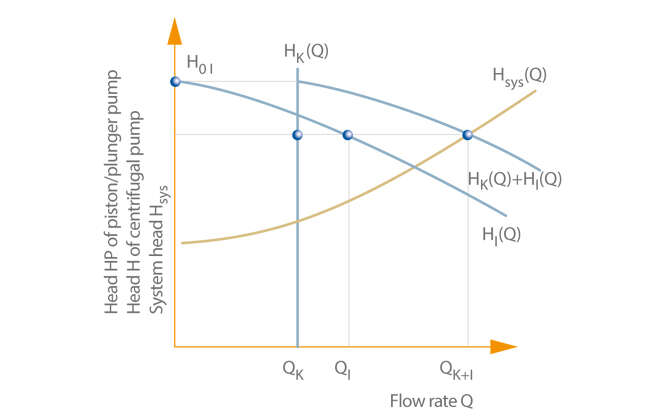

If a plunger or piston pump and a centrifugal pump are operated in parallel, the flow rate of the piston/plunger pump (QK), which is almost constant over the head, is added to the centrifugal pump's flow rate (QI). See Fig. 5 Parallel operation

Fig. 5 Parallel operation: Piston/plunger pump and centrifugal pump