Internal leakage loss

Due to the difference in pressure upstream and downstream of the impeller (see Clearance gap pressure) part of the fluid handled that already has a highe static pressure flows back through the clearance between the stationary and rotating components of the pump (clearance flow).

The loss incurred in the process is referred to as internal leakage loss or clearance gap loss. It can occur between the impeller and the pump casing (see Clearance gap width), in controlled gap seals, at balancing devices and between the individual stages of multistage pumps.

The equations below are used to calculate the clearance flow (Qcl) and the power loss due to internal leakage (PL.cl):

ζcl Clearance flow coefficient

Acl Clearance gap area

Δpcl Difference in static pressure upstream and downstream of the clearance gap

g Acceleration due to gravity

ρ Density of the fluid handled

ηh Hydraulic efficiency

H Head

Acl Clearance gap area

Δpcl Difference in static pressure upstream and downstream of the clearance gap

g Acceleration due to gravity

ρ Density of the fluid handled

ηh Hydraulic efficiency

H Head

The power loss due to internal leakage is influenced by the Reynolds number of the clearance flow, the surface roughness and the geometry of the clearance gap.

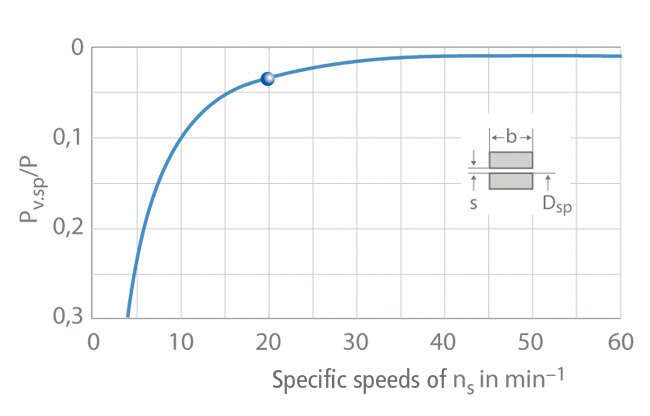

The power loss due to internal leakage (PL.cl) referred to the power input (P) for geometrically similar pumps with geometrically similar clearance gaps is independent of the pump size and the circumferential speed, but significantly dependent on the specific speed (ns).

As shown in the graph for a simple cylindrical clearance gap at the impeller inlet with a relative clearance gap width (s/Dcl) of 0.002 and a relative casing wear ring width (b/Dcl) of 0.133, the internal leakage loss at specific speeds of ns > 20 rpm is negligible.

See Fig. 1 Clearance gap loss

See Fig. 1 Clearance gap loss

Fig. 1 Internal leakage loss: Power loss due to internal leakage, divided by power input, as a function of specific speed of pumps with radial impellers, plotted here for a smooth-surface cylindrical clearance gap of s/Dcl = 0.002 and b/Dcl = 0.133

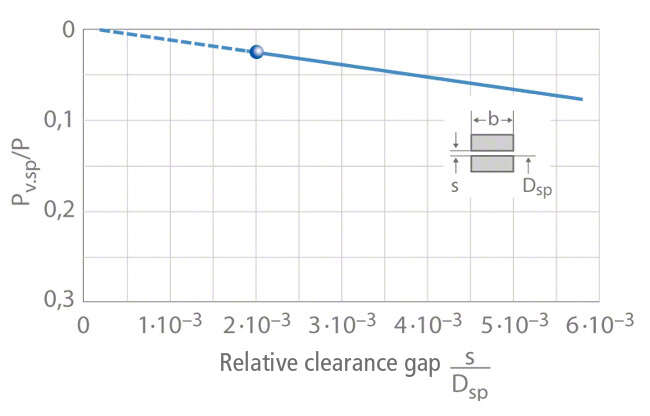

For specific speeds of ns < 20 rpm, a complicated and expensive reduction of the internal leakage losses is worthwhile, e.g. by narrowing the clearance gap. The reduction in internal leakage losses is almost linear in relation to the decrease in gap width. See Fig. 2 Internal leakage loss

Fig. 2 Internal leakage loss: Power loss due to internal leakage, divided by the power input of a volute casing pump with a specific speed of ns = 20 rpm and a smooth-surface cylindrical clearance gap of b/Dcl = 0.133, plotted as a function of relative clearance gap width

By using clearance surface types such as circumferential grooves, honeycomb and cellular surfaces, it is possible to minimise internal leakage losses in centrifugal pumps. This, however, reduces the centring restoring force of the clearance essential for smooth operation (Lomakin effect).