Coupling alignment

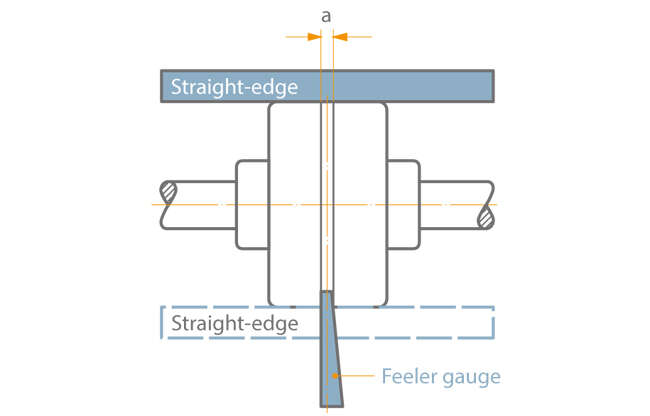

Coupling alignment is essential to ensure the trouble-free mechanical operation of a pump set and to avoid damage to the transmission elements. It involves maintaining the prescribed distance (a) between the coupling halves (see Shaft coupling). See Fig. 1 Coupling alignment

Fig. 1 Coupling alignment: Flexible coupling alignment using straight-edge and feeler gauge

Furthermore, the shaft centrelines must be precisely aligned with one another at the coupling, and any lateral, height or angular misalignment must be compensated. See Figs. 3, 4 Coupling alignment

Fig. 3 Coupling alignment: Lateral or height misalignment

Fig. 4 Coupling alignment: Angular misalignment

The alignment should be checked, preferably by means of a straight-edge and feeler gauge. See Fig. 1 Coupling alignment

A coupling is correctly aligned if a straight-edge laid across both coupling halves parallel to the shaft maintains the same distance from the shaft at all points around its circumference. In addition, the axial distance between the coupling halves should remain the same at all points around the circumference.

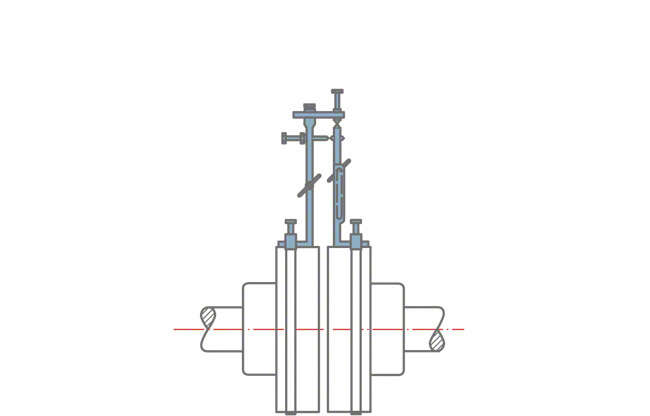

Accurate alignment can be achieved quickly using an alignment jig. See Fig. 2 Coupling alignment

Fig. 2 Coupling alignment: Flexible coupling alignment using an alignment jig

The required degree of coupling alignment accuracy depends mainly on the coupling type and the rotational speed In the case of hot water pump coupling alignment, it is important to observe the pump manufacturer's special instructions relating to thermal deformations associated with hot water pumps. After completing coupling alignment, it is advisable to pin the pump incl. drive to the baseplate or pump foundation, to prevent shifting of the pump set during operation.