Battery metals for mobility transition: How pumps sustainably advance mining

Electric cars have triggered a rapid increase in demand for metals such as lithium, copper, cobalt and nickel. Covering this demand is becoming more and more difficult. How can we expand mining of these critical metals with a minimum impact on the environment? Durable and water-saving pumps make mining more efficient, safer and more environmentally friendly – contributing significantly to the sustainable future of mobility.

From lithium to cobalt: Electric cars require numerous critical metals

The materials needed for manufacturing an electric car differ from those of a combustion engine car. An internal combustion engine is a lot heavier than an electric motor, however, it is mainly made of iron alloys or aluminium alloys. By contrast, the motors of electric cars require many hundreds of metres of copper cable and frequently also permanent magnets, involving rare earths such a neodymium.

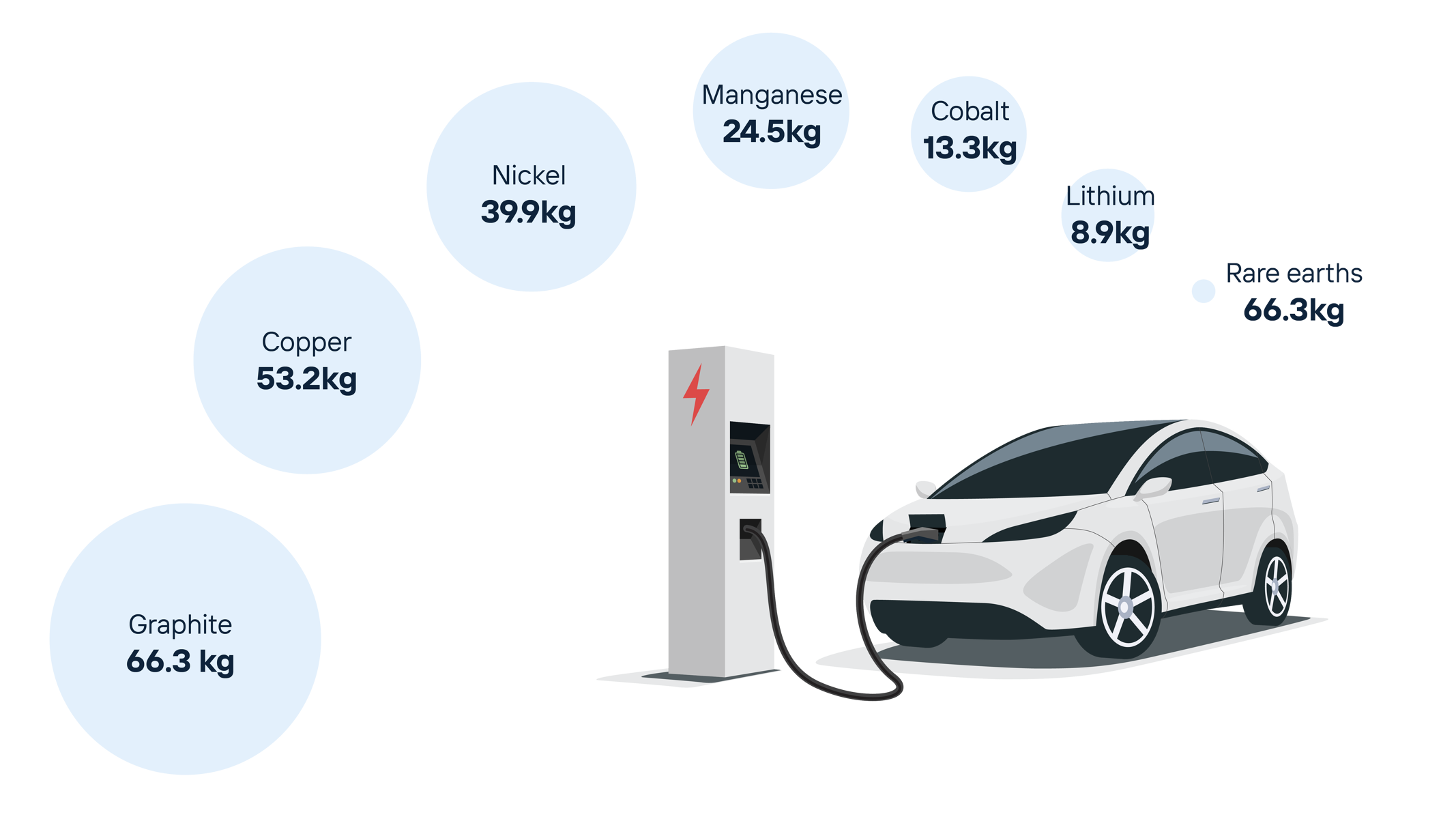

Battery metals required for an electric car with a 75 kWh battery

Source: IEA

Excluding steel and aluminium, an electric car contains about six times the amount of metals and minerals of a combustion engine car, estimates the International Energy Agency (IEA)(opens in a new tab). A car with a combustion engine only comprises 22 kilograms of copper and 11 kilograms of manganese, compared to an electric car with 206 kilograms of metal and minerals such as copper, manganese, lithium or graphite. The rising demand for these minerals is an enormous challenge for the mining industry. To enable the large-scale production of electric cars new pathways have to be found to secure a reliable supply with critical resources – a balancing act between technological progress and sustainable use of resources.

Pumps are essential for satisfying resource demand

To be able to cover the demand for battery metals triggered by electric cars, major investments into mining are pivotal. Pumps play an indispensable role in this process: from draining deep mines to pumping lithium brine from salt lakes and transporting abrasive sludge in ore processing. Here are three examples of KSB innovations that make mining more efficient and sustainable.

KSB's innovations make mining more efficient and sustainable

Our innovative pump solutions enhance mobility transition by minimising energy input, water consumption and wear in mining. In this way they not only protect the environment, they also lower the operating costs for the operators. A key factor is the use of specially developed materials. The Gasite® alloy family, which was created in the 1940s and has continuously been developed until today by KSB GIW, ensures the durability and resistance of mining pumps. For a plus in resistance Endurasite™ alloys are used, the standard material for wetted parts of the MDX series. IIoT (Industrial Internet of Things) technology reduces downtimes and extends the service life of the pumps by monitoring wear and signalling when maintenance is needed. It also ensures that pumps are always operated at their optimum.

LAPIS is the first mechanical seal by KSB that has been exclusively developed for KSB GIW® slurry pumps.

Sustainability and profitability in mining are not opposites. Barrier-water-free shaft seal arrangements for slurry pumps not only spare natural resources, they also lower the total cost of ownership. With their expeller seal, pumps of the TDW type series are suitable for recovering water. For the LCC type series, KSB has developed the LAPIS mechanical seal – another seal that works without barrier water. This seal is characterised by its springs being located outside the fluid handled, where they are protected from solids by an external quench fluid, such as water or grease. A clamping collar mechanism enables maximum torque transmission and easy adjustment.

KSB GIW, Inc.'s commitment to environmental protection is not limited to innovative pump solutions – they also consistently opt for sustainable solutions for their own operations. By purchasing renewable energy certificates the company ensures that its production facilities are powered one hundred percent by renewable energies. KSB further promotes a circular economy with its comprehensive scrap metal buyback programme: Worn pumps and parts are recycled. About sixty to seventy percent of the new slurry pumps are made of recycled white iron. This is how KSB holistically contributes to a more sustainable future – from product development through to operations management.