How can pumps help protect the climate?

Efficient pumps help to protect the climate

Many new climate records were reached in 2023. It was the hottest year(opens in a new tab) ever recorded and the extent of the Antarctic sea ice reached a historical low. Extreme climate anomalies also occurred, such as forest fires in Hawaiii(opens in a new tab) and floods in China(opens in a new tab). To minimise the effects of climate change, we need to reduce greenhouse gas emissions. Highly efficient pump systems can play an important role in achieving this.

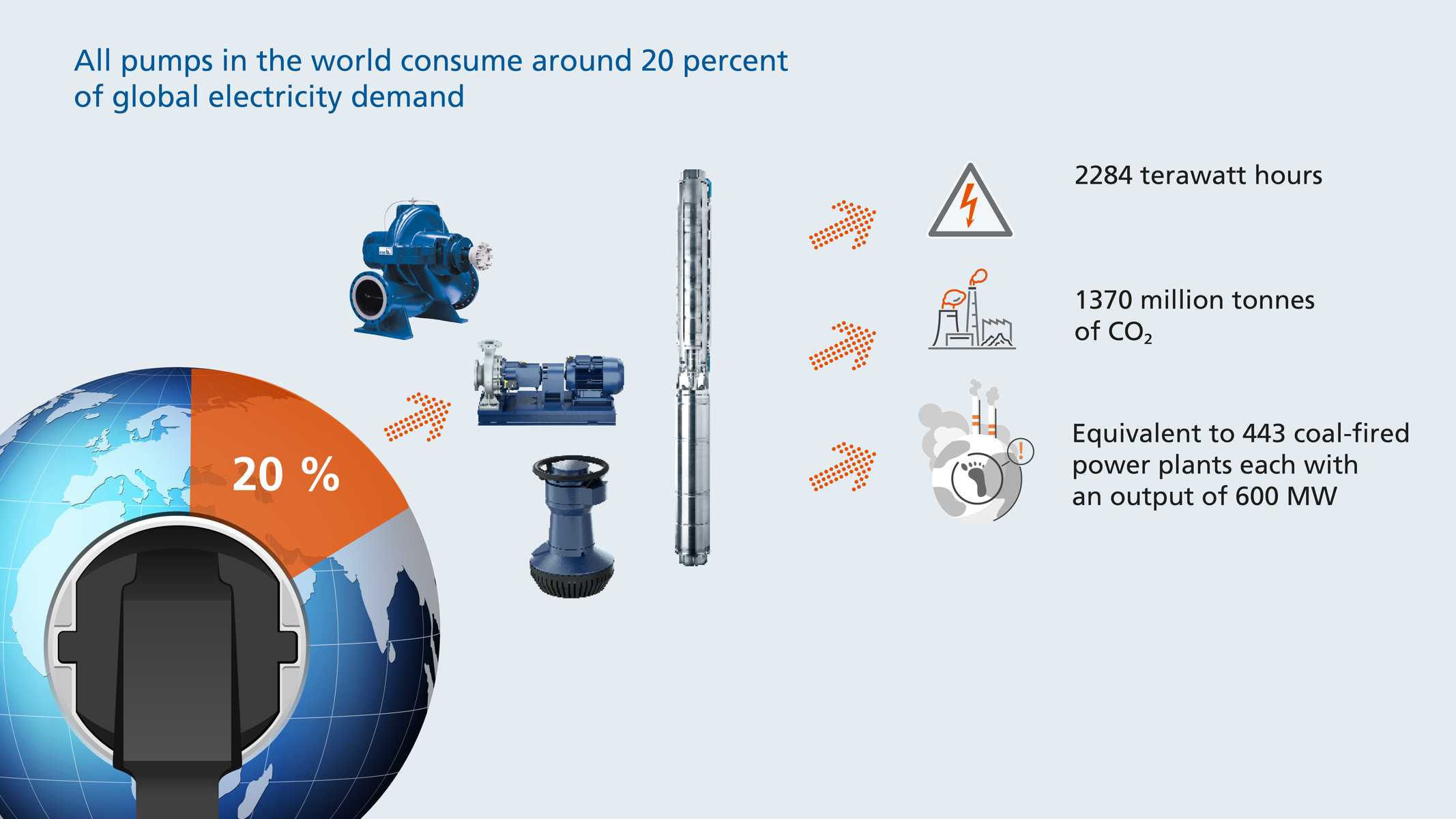

Pumping systems account for 20 percent of global energy consumption

Accounting for 20 percent of global energy consumption(opens in a new tab), the role played by pumping systems in efforts to combat climate change should not be underestimated. This corresponds to 2284 terawatt hours, which amounts to around 1370 million tonnes of CO₂ equivalent – roughly the emissions of 443 coal-fired power plants in one year. Importantly, it is not only the pumps that consume this energy, but the entire systems in which they are operated.

How can we reduce pump energy consumption? One answer is to develop more efficient pump models and manufacture them in a more environmentally friendly way. For example, our new AmaRex Pro has been designed to guarantee the best possible performance. With IE5-equivalent motors and maximum hydraulic efficiency, our pump systems operate at high efficiency levels and reduce our customers’ energy consumption. KSB’s development engineers have also designed the motors with five percent less copper than the previous model while the pump casings are largely made of recycled cast iron and some of the steel is also recycled. This supports the circular economy and means fewer greenhouse gas emissions. Besides our products, we are also making our production facilities more climate-friendly. For example, our plant in Lille, France, where our AmaRex Pro is manufactured, is set to reduce its greenhouse gas emissions by 98 percent in 2027 compared with 2021. This is being achieved through effective system insulation, efficient heating systems, LED lighting and photovoltaic systems.

However, the operation of pumps offers far more potential for saving energy than their production. In fact, 95 % of a pump’s carbon footprint is caused by the electricity it consumes during use. The potential for optimisation is huge, with experience showing that optimisation measures can reduce a pump system’s energy consumption by 40 % on average. If this approach were to be applied to all pump systems worldwide, CO₂ emissions equivalent to 89 coal-fired power plants could be saved every year.

How can pump systems be optimised to use less energy?

This holistic approach to optimising the entire system potentially offers not only the most energy savings, but also the greatest improvements in terms of system reliability and reduced maintenance. It also reduces life cycle costs for our customers, with energy alone accounting on average 45 % of these costs(opens in a new tab). KSB has set itself the goal of saving 850,000 tonnes of CO₂ per year by 2025 through such optimisation measures.

KSB offers its customers solutions to reduce their energy consumption as far as possible. Besides providing highly energy-efficient products and options for monitoring and control, we also advise customers to ensure that their pumps are correctly dimensioned for the application and are operated at variable speed according to the load profile. On top of this, we offer CO₂ emission calculations to provide customers with a solid basis for decision-making.

Even if a system has already been installed, there is still plenty we can do to save energy. Our SES System Effizienz Service®(opens in a new tab) experts carefully examine and analyse the systems on site, determine the actual load profile of the pumps and compare it with the design conditions. After identifying impermissible pump operating conditions and critical system conditions, they make specific recommendations to reduce energy consumption and the carbon footprint.

More sustainable, more reliable, lower costs

KSB has set itself the goal of saving 850,000 tonnes of CO₂ per year by 2025 by optimising our customers’ systems. Besides helping them to achieve their sustainability targets, the improvements also enable our customers to significantly reduce the life cycle costs of their pump systems. Depending on the pump type and application, energy costs account from 20 % to as much as 90 % of these costs. Further advantages include increased system reliability and lower maintenance costs. As well as providing highly energy-efficient products and options for monitoring and control, we also advise customers to ensure that their pumps are correctly dimensioned for the application and are operated at variable speed according to the load profile. On top of this, we offer CO₂ emission calculations to provide customers with a solid basis for decision-making.

Even if a system has already been installed, there is still plenty we can do to save energy. Our SES System Effizienz Service®(opens in a new tab) experts carefully examine and analyse the systems on site, determine the actual load profile of the pumps and compare it with the design conditions. After identifying impermissible pump operating conditions and critical system conditions, they make specific recommendations to reduce energy consumption and the carbon footprint.

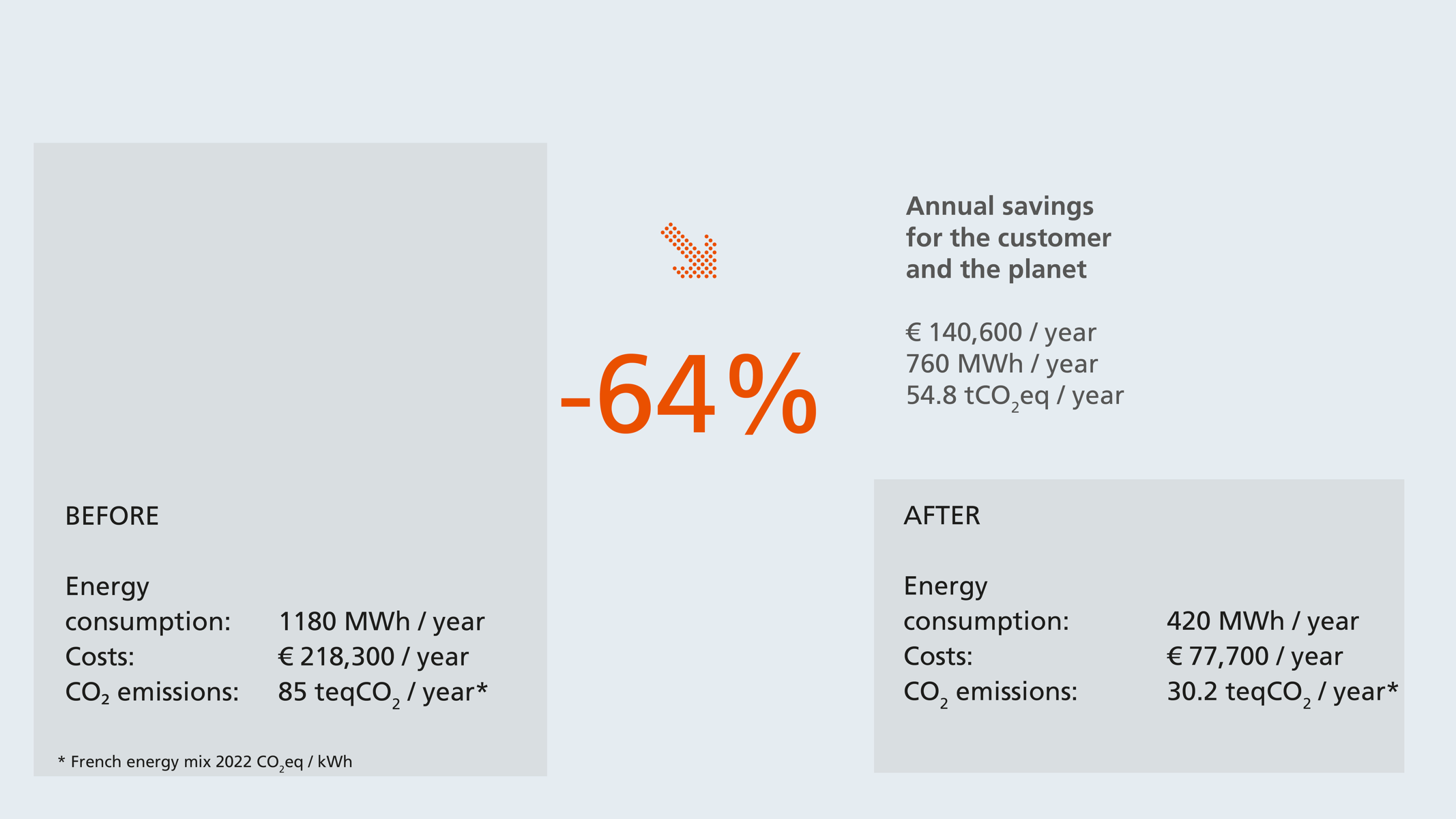

Payback period of four months – an example from practice

How much energy can be saved by optimising a pump system? Let’s take a look at the practical example of a water treatment plant in France. Five Etanorm 200 pumps with IE1 motors were being used there. After a comprehensive system analysis, KSB found that only 36 percent of the energy were being used effectively – 64 percent were being wasted. The KSB experts recommended installing five smaller groups of Etanorm 125 pumps with IE4 motors, variable speed control, a pump measuring unit and a KSB protection system. The results were impressive: The customer not only saved 140,600 euros per year, but also reduced their energy consumption by more than 50 % and saved the equivalent of 54.8 tonnes of CO₂ per year. This would be the equivalent of a new car compliant with EU emission targets driving at 80 km/h for ten months non-stop – and all this with a payback period of just four months!