How can we solve the waste water problems of megacities?

The growth of our cities can overburden the existing waste water disposal systems

More than half of the world's population now lives in cities – and the trend is still rising. According to United Nations estimates, 68 % of people will live in urban areas by 2050. The number of megacities with more than ten million inhabitants will grow to over 40 in the next 30 years. The size of these cities poses challenges for utilities and urban planners. How can they deal with the huge volumes of waste water that are produced?

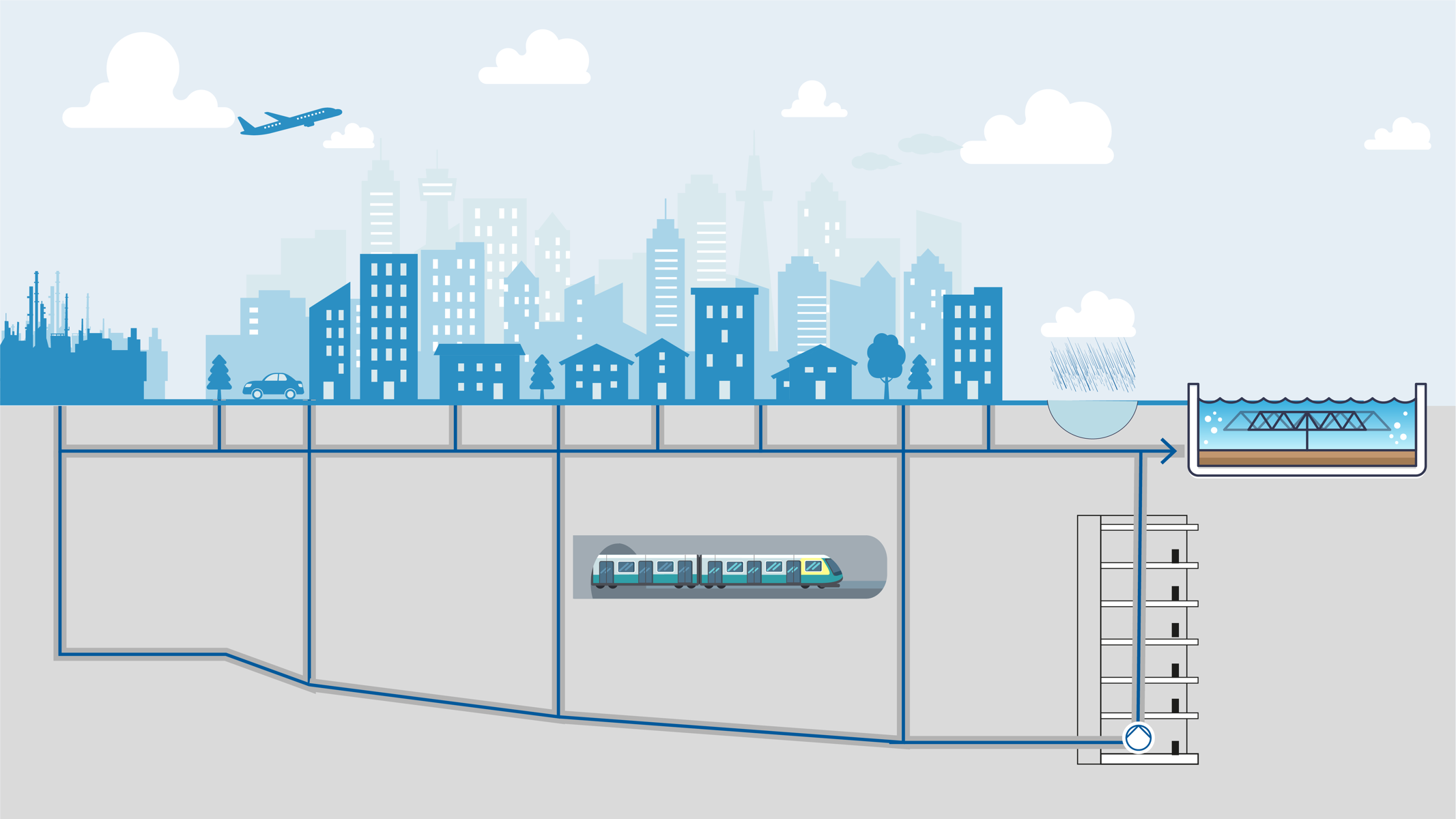

How deep tunnels solve the waste water problems of big cities

London solved its waste water problem with a "deep tunnel". This is a tunnel system that usually has a diameter of three metres or more. Such systems are constructed with tunnel boring machines deep below cities where there are no more pipelines or underground shafts.

These gigantic pipes collect waste water, rainwater or combined sewage and lead it to underground pumping stations. In doing so, they serve not only as a conduit, but also as a reservoir in the event of heavy rainfall.

A growing number of major cities are turning to deep tunnels to solve their waste water problems – in addition to London, for example, Chicago, New York, Singapore and Hong Kong.

During heavy rainfall, a deep tunnel accepts the increased volumes of water and thus prevents the sewage system from overflowing.

A practical example: Auckland Central Interceptor

A current project in Auckland, New Zealand, in which KSB is involved, shows how the construction of such a deep tunnel works. Like London in the past, the city has the problem that waste water and stormwater flow into a combined sewer network. During heavy rainfall, its capacity is insufficient, which means that untreated waste water has to be discharged into the rivers.

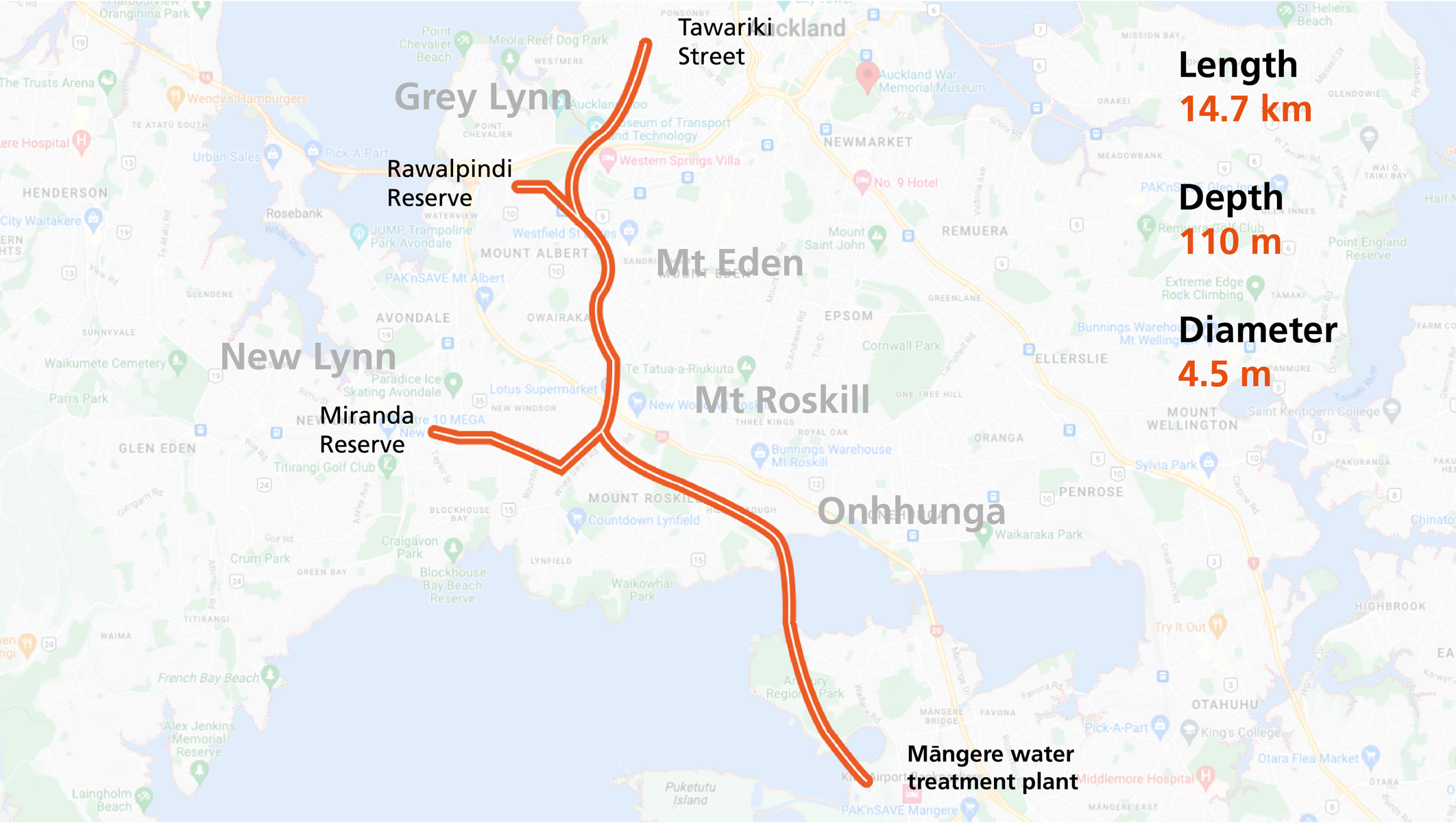

That is why the city decided to build a deep tunnel: the Central Interceptor tunnel is to have a diameter of up to 4.5 metres and a length of 14.7 kilometres. It will run from the Grey Lynn district in the north-west under Auckland's inner city and harbour to Māngere in the south-east.

The Central Interceptor tunnel in Auckland is designed to channel water masses out of New Zealand's largest city during heavy rainfall.

Currently, two German-made tunnel boring machines, named Hiwa-i-te-Rangi and Dominca, are boring the tunnels. When completed, the Central Interceptor will be between 15 and 110 metres below the surface.

Together with two smaller connecting tunnels, it will collect the waste water and convey it to the Māngere pumping station at a gradient of 1:1000. There, KSB pumps transport the water from a depth of 40 metres into a water treatment plant.