Etanorm: 90 years of efficiency and versatility

Development of the Eta family

The word “standardised” in standardised water pump is somewhat misleading. After all, Etanorm is one of the pumps with the greatest wealth of variants. The batch size of all pumps of this type series sold is around 1.4. However, the wide range of sizes and materials ensures that the user gets a pump that is ideally suited for their particular conditions of use. A pump with an impeller trimmed to match the operating point also guarantees low-wear operation.

The challenge faced by the team of development engineers for the current generation of the classic best-seller began with a simple question: How can we set new standards with a pump that already impresses with its low energy consumption, reliability and durability? After much debate, there were two aspects that provided a reason for a renewed technical overhaul and optimisation of the Etanorm.

The hydraulic system is key to efficiency

A pump's hydraulic system remains the key to ensuring high efficiency and low energy consumption. Generally speaking, Etanorm pumps continue to impress with their optimised hydraulic systems. Thanks to their closely-spaced selection chart, it is almost always possible to select a size whose operating point is close to the best efficiency point. In addition to the hydraulic system and trimmed impeller, variable speed operation combined with a highly efficient drive are instrumental in keeping down energy and operating costs.

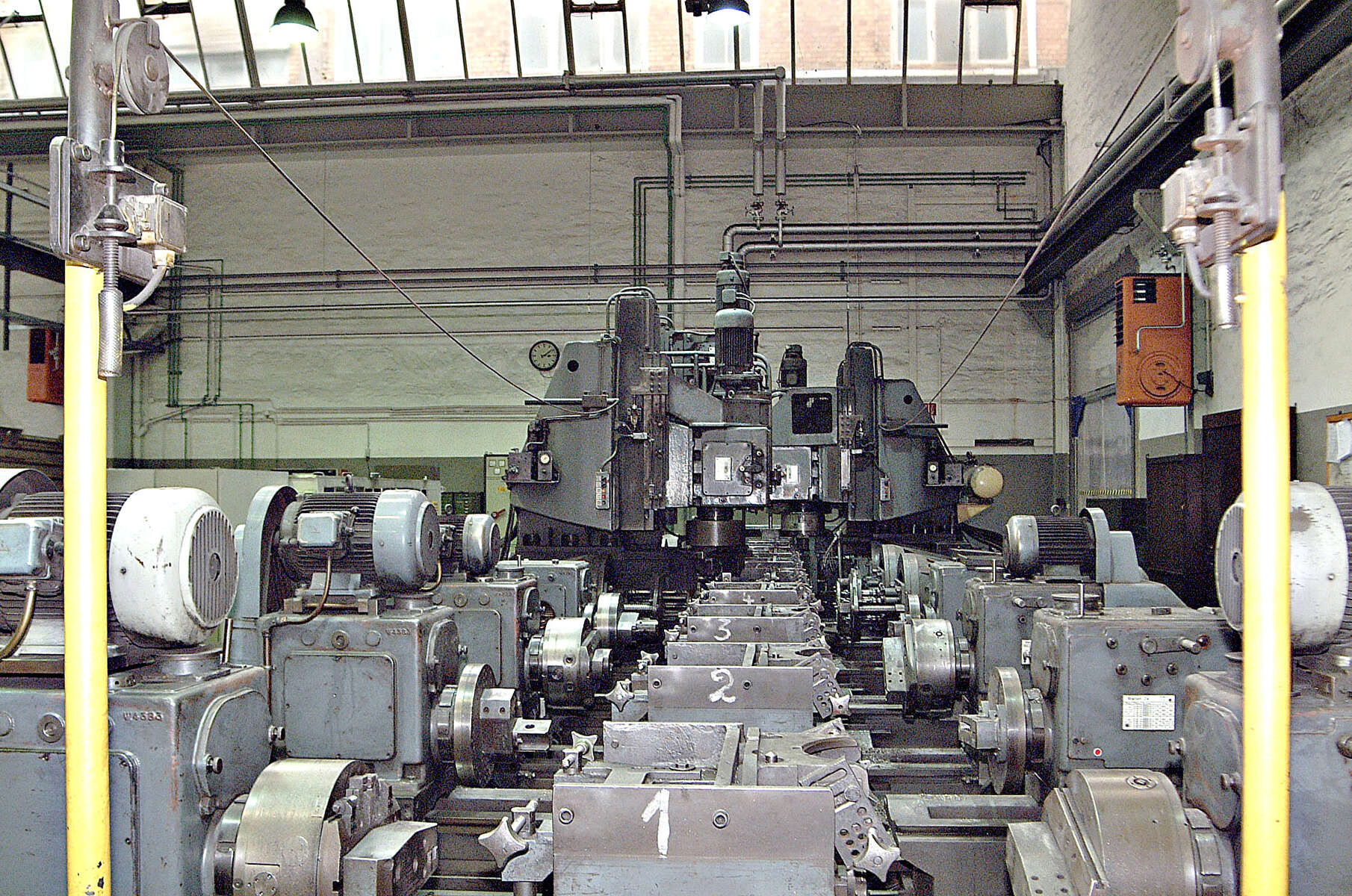

In 1955, the first automatic production line for machining Eta components went into operation in Frankenthal.

A total of 62 sizes is available. The finite element method (FEM) and computational fluid dynamics (CFD) were used for the hydraulic optimisation of individual sizes. Engineers used these tools to create the hydraulic contours and verified them in comprehensive tests.

Etanorm is a classic clean water pump that is not normally used to transport abrasive media. However, as solids were increasingly playing a role, the shaft seal chamber was therefore designed to be more compatible with solids than the previous version. To adapt the pump to the fluid handled, users can choose from various materials for the casing and impellers as well as for the mechanical seals.

Global production to uniform quality standards

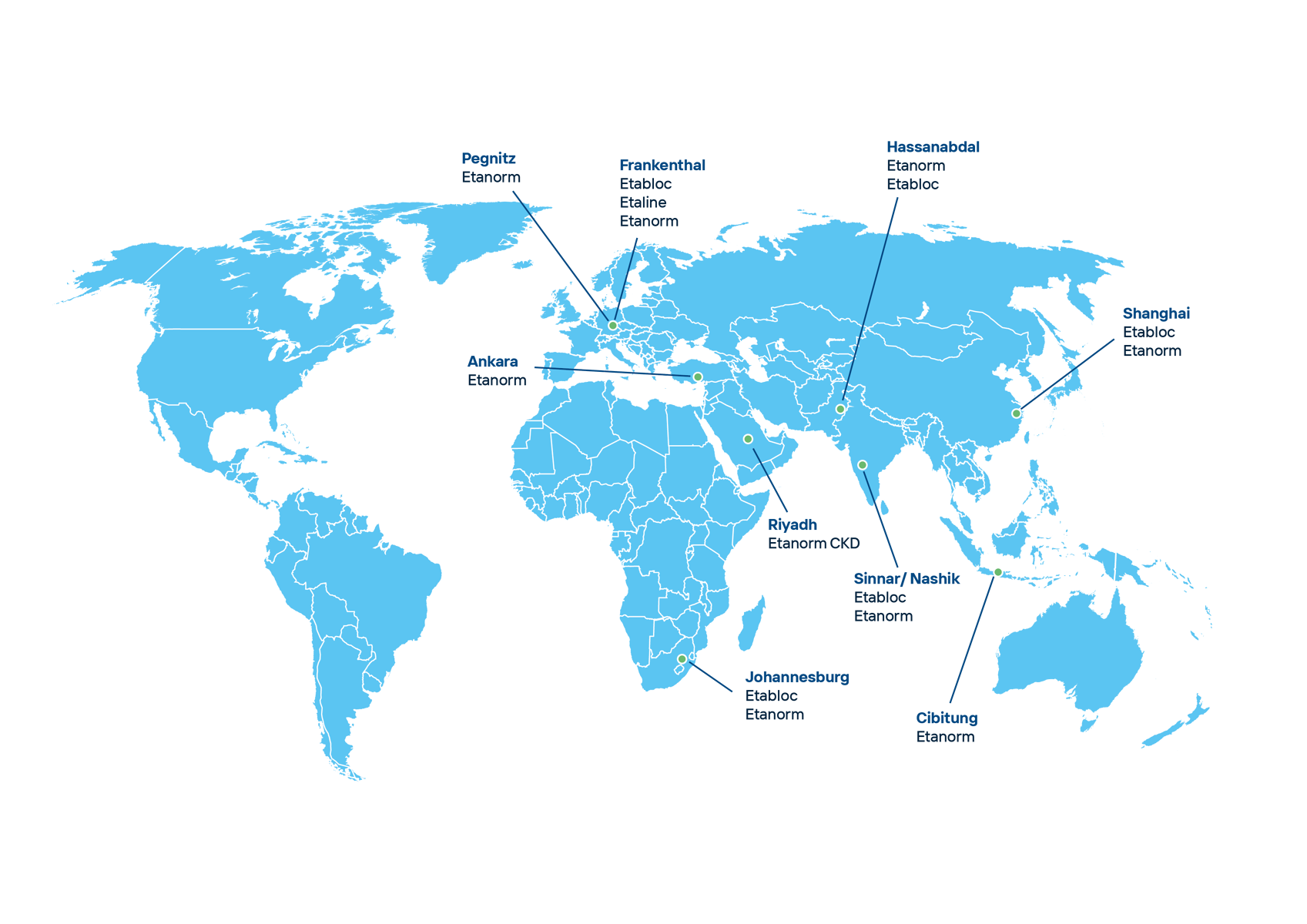

Today, Etanorm is manufactured to the same quality standards in all factories worldwide. In addition to EN flanges, the pumps are also available with ASME flanges. Users receive a pump that is manufactured to the same quality and development specifications at all production locations in Germany, China, Turkey, India, Indonesia, Pakistan, Saudi Arabia and South Africa. This has made global procurement considerably easier and increased the availability of pumps and spare parts. For example, an Etanorm pump can be easily installed in pipelines requiring an EN-type or ANSI-type flange.

Although quality standards are the same everywhere, it is as important that each pump is individually tailored to match local conditions. Pumps and accessories have to be capable of being adjusted to regional requirements quickly, easily and reliably. Thanks to KSB’s close-knit global sales and service networks, spare parts quickly reach their point of use.

Virtual impeller trimming enables maximum flexibility

The next step in Etanorm’s evolution was to combine it with the Industry 4.0-compatible MyFlowDrive 2, which allows a desired fixed speed to be set individually on the motor using virtual impeller trimming. This provides the user with planning reliability as the flow rate of the pumps can be increased or decreased quickly and easily. The conventional approach for fixed speed pumps is to match the flow rate and head to the calculated design point by trimming the impeller. However, this is done during the manufacturing process of the pump and can only be corrected later with substantial effort.

As the supply voltage of the synchronous motor is modulated by the motor-mounted frequency inverter, the motor can be operated on almost any power grid worldwide. For global engineering contractors in particular this is a huge advantage because it means they no longer need to consider the local mains voltage when selecting pumps.

Worldwide production sites for the KSB Etanorm and Etabloc type series

Due to its wide-ranging selection chart and numerous material and mechanical seal variants, Etanorm will remain the first choice in many industries and applications when it comes to cost-effective fluid transport.

KSB invests in modernising Eta production

To ensure that its Frankenthal location remains competitive in future, KSB is comprehensively modernising its Eta production facility by 2029 in line with the latest technological and energy standards. From 2026, the Eta production facility at KSB’s headquarters in Frankenthal will be expanded to become the competence centre for the latest generation of electronically controlled pumps in Europe. KSB will be investing around 70 million euros in this over the next few years – one of the largest single investments the company has ever made.

The new buildings will create sufficient space to restructure the machining, assembly and logistics areas and to completely refurbish older parts of the production hall before they are used again. The plans for the energy-efficient redesign of production also include connecting the drying system of a new paint shop to the local heating network of the new heating station located at the headquarters and installing photovoltaic systems on the roofs. KSB is already manufacturing the new, energy-efficient and sustainably produced EtaLine Pro pump generation for building services applications at its Frankenthal-based Eta production facility.