The perfect solution, layer by layer: Parts On Demand in practice

Whether it's complex designs, difficult material properties or simply the time factor, when a highly specific part is required, finding the right partner is often a time-consuming process. We support customers by providing individual solutions for their challenges via our made-to-order additive manufacturing service.

Discover some of the highlights of our KSB SupremeServ Parts On Demand service.

Whether it's complex designs, difficult material properties or simply the time factor, when a highly specific part is required, finding the right partner is often a time-consuming process. We support customers by providing individual solutions for their challenges via our made-to-order additive manufacturing service.

Discover some of the highlights of our KSB SupremeServ Parts On Demand service.

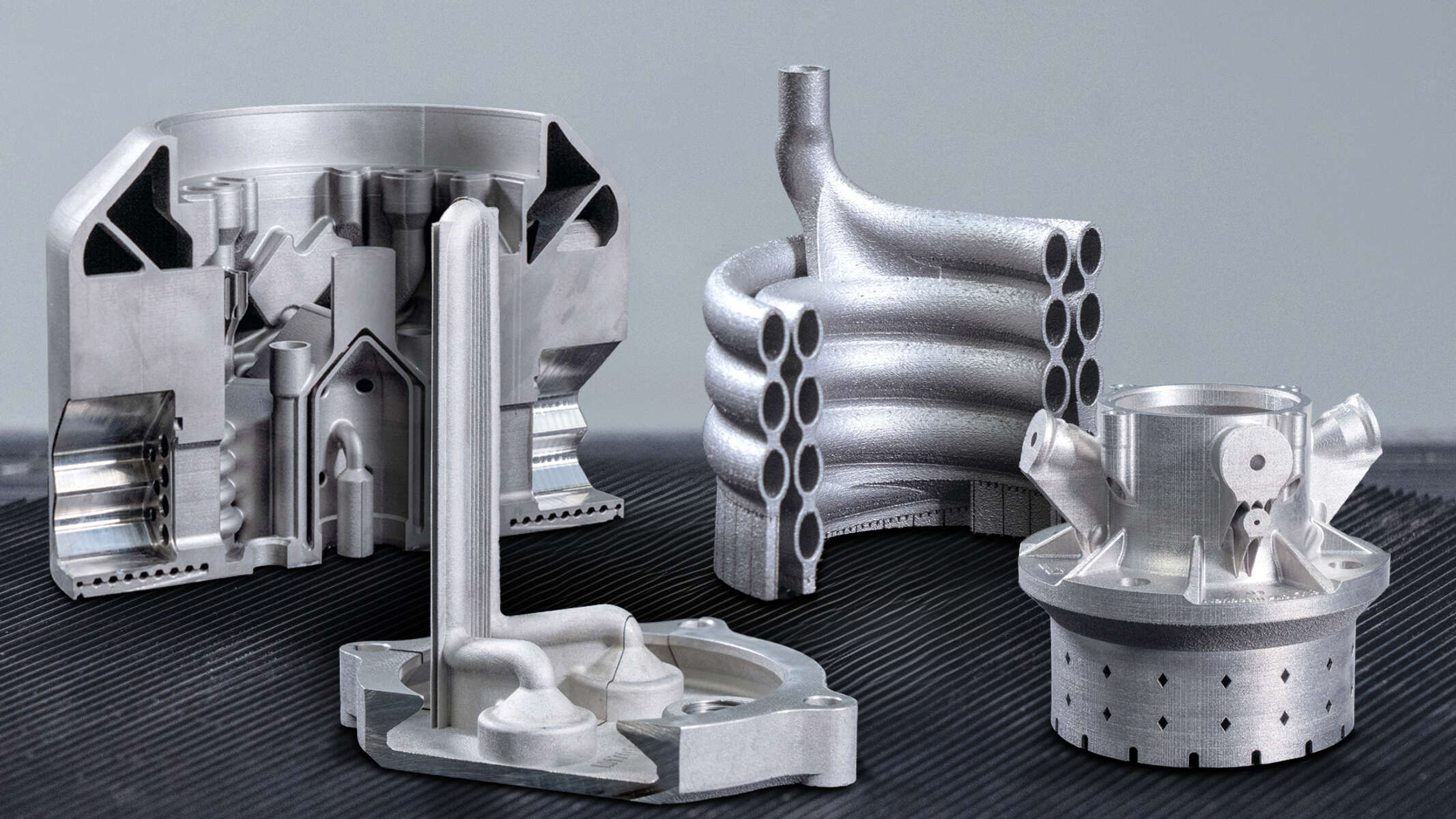

High-efficiency heat exchangers

- Item 1

- Item 2

- Item 3

- Item 4

Components for molten salt reactors

- Item 1

- Item 2

- Item 3

Special components

- Item 1

- Item 2

- Item 3