Maximal effektivitet – jobba effektivt med Eta-familjen

Etanorm/Etanorm MyFlow/Etanorm Pro

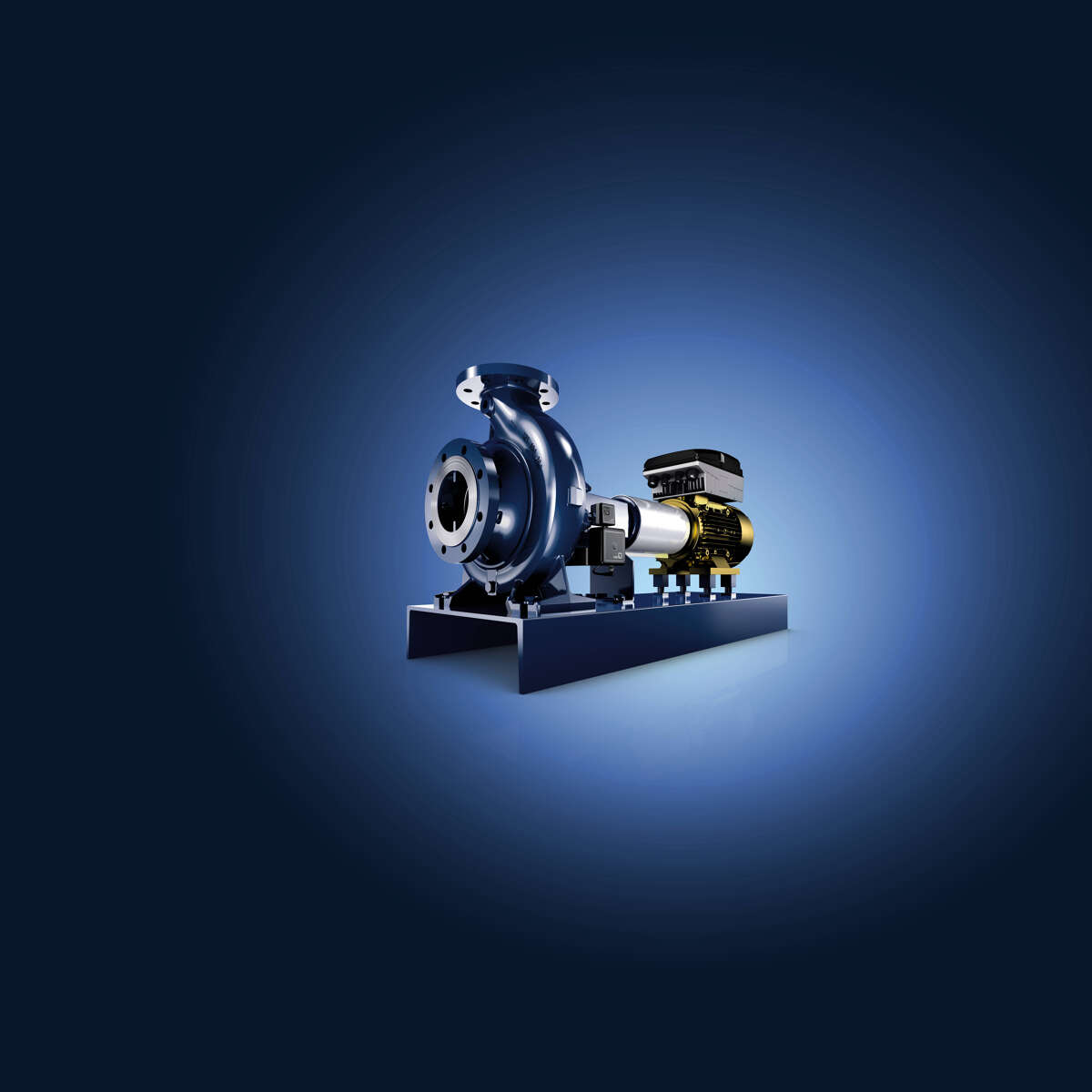

Single-stage volute casing pump in back pull-out design, with ratings and main dimensions to EN 733, with IEC-compatible power drive system comprising PumpDrive 2 and KSB SuPremE® motor or PumpDrive 3 (efficiency class IE4/IE5 to IEC TS 60034-2-3:2016) and motor-integrated frequency inverter. The pump is designed with replaceable casing wear rings, closed radial impeller with multiply curved vanes, single mechanical seal or double mechanical seals to EN 12756, shaft equipped with replaceable shaft protecting sleeve in the shaft seal area. The back pull-out design allows the coupling, bearing brackets and impeller to be dismantled without the need to disconnect the pump casing from the piping. Motor mounting points in accordance with IEC 60072, envelope dimensions in accordance with DIN V 42673 (07-2011). ATEX-compliant version available. Well ahead of the ErP Directive's efficiency requirements.

Etabloc/Etabloc Pro/Etabloc MyFlow

Single-stage volute casing pump in close-coupled design, with ratings to EN 733, with IEC-compatible power drive system comprising PumpDrive 2 and KSB SuPremE® motor or PumpDrive 3 (efficiency class IE4/IE5 to IEC TS 60034-2-3:2016) and motor-integrated frequency inverter. Shaft fitted with a replaceable shaft sleeve in the shaft seal area. Volute casing and casing cover with replaceable casing wear rings. Volute casing with integrally cast pump feet for variants B, C and S. Motor mounting points in accordance with IEC 60072, envelope dimensions in accordance with DIN V 42673 (07-2011). ATEX-compliant version available. Well ahead of the ErP Directive's efficiency requirements.

KSB SuPremE

IEC-compatible sensorless magnetless synchronous reluctance motor (exception: motor sizes 0.55 kW / 0.75 kW with 1500 rpm are designed with permanent magnets) of efficiency class IE4 / IE5 (Super/Ultra Premium Efficiency) to IEC TS 60034-30-2:2016 for operation on a KSB PumpDrive 2, PumpDrive 2 Eco or PumpDrive R variable speed system. Suitable for connection to three-phase 380-480 V power supply (via PumpDrive). The motor mounting points comply with IEC 60072 specifications to ensure compatibility with standardised IEC frame motor applications and full interchangeability with IE2 or IE3 standardised asynchronous motors. Envelope dimensions lie within the limits for IE2/IE3 motors as recommended in DIN V 42673 (07-2011). The motor is controlled without rotor position sensors. The efficiency of the motor also exceeds 95 percent of nominal efficiency when the motor runs at 25 percent of its nominal power on a quadratic torque-speed curve. The motor is magnetless which means that so-called rare earths are not used in production. Drive production is thus sustainable and environmentally friendly.

PumpDrive 2/PumpDrive 2 Eco

Modular self-cooling frequency inverter that enables continuously variable speed control of asynchronous and synchronous reluctance motors by means of analog standard signals, a field bus or the control panel. As PumpDrive is self-cooling, it can be mounted on a motor, on the wall or in a control cabinet. Up to six pumps can be controlled without needing an additional controller.

PumpMeter

Device for monitoring the operation of one pump. It is an intelligent pressure transmitter for pumps, with on-site display of measured values and operating data. It records the load profile of the pump in order to indicate any potential for optimising energy efficiency and availability. The device comprises two pressure sensors and a display unit. PumpMeter is supplied completely assembled and parameterised for the pump it is used with. It is ready for operation as soon as the M12 plug connector is plugged in.