KSB underground: deep tunnels for waste water transport

Today, more than half of the world’s population live in urban areas – and the trend is rising. Researchers predict that another 2.5 billion people will move into cities over the next 30 years. This means immense challenges for urban planners.

Megacities: Challenges for urban planners

Increasing urbanisation is driving growth in cities and their populations. The number of megacities with more than 10 million inhabitants will grow to over 40 in the coming years. The key challenges facing urban planners range from suitable housing schemes to intelligent traffic planning and crucial questions including: How to handle the huge amounts of waste water which cities generate?

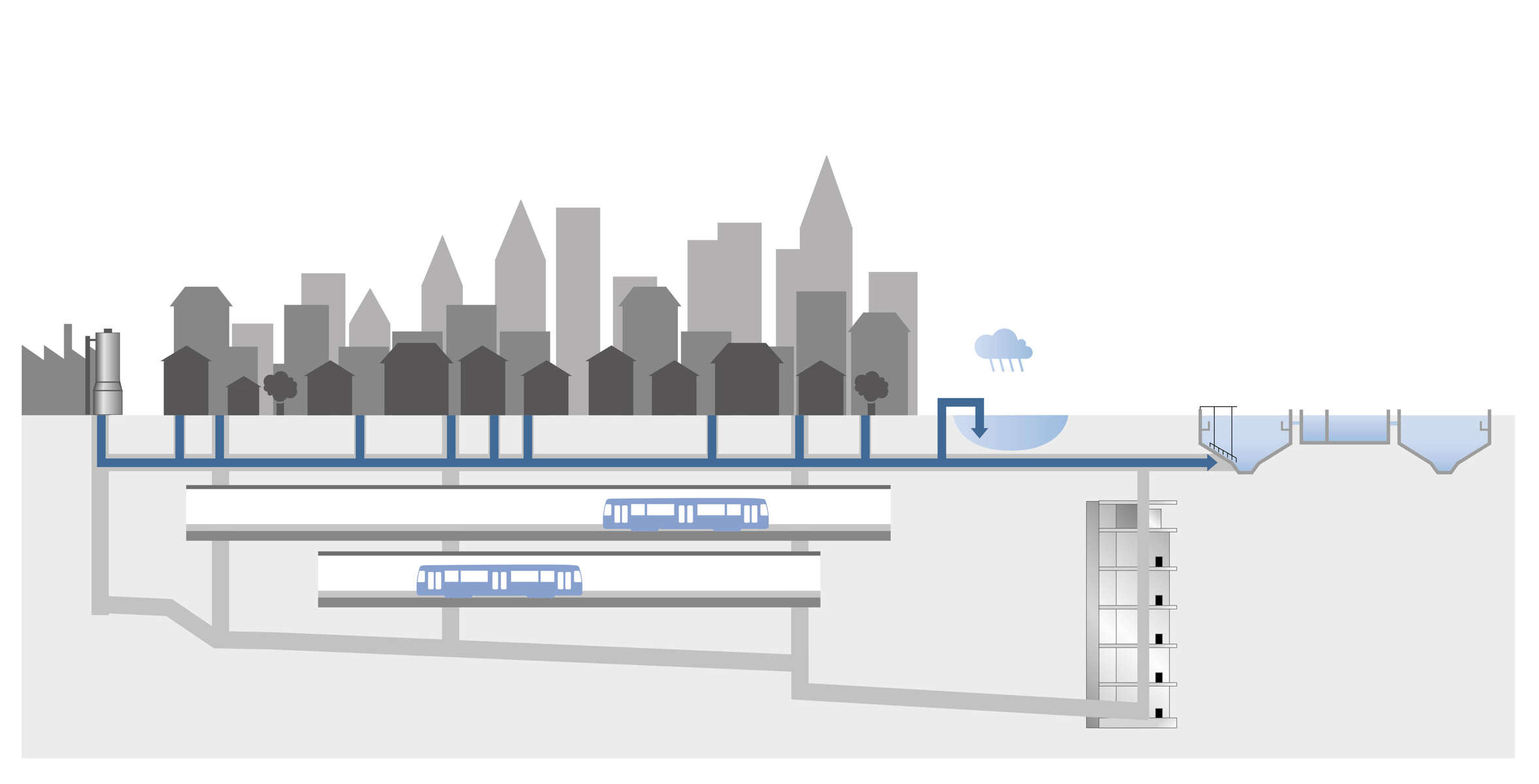

One potential answer is “deep tunnels.” Here, waste water is collected deep underground in large pipes or tunnels measuring several metres in diameter. It flows by gravity to pumping stations outside the city, where it is pumped back to the surface and processed in waste water treatment plants.

The challenges in planning and constructing such deep tunnels are extensive: Firstly, they must not interfere with infrastructure like cable shafts, district heating, drinking water and gas lines or existing tunnels for cars or underground rail systems. And secondly, they are of course affected by local geological conditions. For example, tunnels may have to be laid deeper to avoid the problems of tunnelling through layers of sand or rock. Depending on the length and gradient of the pipeline, these deep tunnels can run at a depth of 60 metres or more below the surface.

The London underground: Lee Tunnel stores and drains sewage and stormwater

London’s Lee Tunnel offers a good example of a deep tunnel: With a diameter of seven metres, it can accommodate and temporarily store around 382,000 million cubic metres of stormwater. The tunnel – whose £675 million budget made it the most expensive water project ever tendered in the UK – was completed in 2015.

It forms part of a longer tunnel which will ultimately extend over a total length of 39 km and include over 40 shaft structures. It will follow the course of the Thames at a depth of 25 to 80 metres. This makes it the deepest tunnel in London and one of the deepest waste water tunnels in Europe.

Principle of a deep-tunnel lifting station

KSB’s deep-tunnel projects: meaningful contributions to a cleaner environment

Deep tunnels have the advantage that their use is not limited to the removal of waste water – they can also offer useful temporary storage for stormwater or combined sewage. If only one pipe is used for both sewage and stormwater, heavy rain can lead to the volume of combined sewage exceeding the capacity of the treatment plant. Routing large quantities of stormwater into the waste water treatment plant can risk compromising its biological treatment processes. Deep-tunnel projects allow combined sewage to be stored in tunnels and fed to waste water treatment plants in a controlled manner after rainfall. This greatly reduces environmental pollution.

An overflow of combined sewage into natural waterways can thus be avoided until the storage capacity of the tunnel is reached. In many large cities, combined sewage is currently still discharged directly into lakes or rivers during heavy rainfall.

KSB pumps for handling waste water: the Sewatec SPN type series

KSB's product portfolio includes various pump type series capable of pumping large volumes of waste water to high heads.

The Sewatec SPN type series is specifically designed for deep-tunnel projects and is generally the favoured choice for this type of application.

Advantages of the Sewatec SPN:

- The Sewatec SPN is a non-clogging vertical waste water pump in dry installation.

- Dry installation facilitates maintenance.

- Thanks to its vertical design, the pump has a relatively small footprint. This can reduce costs for installation in deep pumping station shafts.

- The type series’ selection chart ranges up to a maximum flow rate of 6.5 m³/s and a maximum head of 100 m.

- The hydraulic systems are based on well-proven waste water hydraulic systems. They are designed with a free passage of up to 350 mm.

Learn more about the Sewatec SPN type series

For smaller waste water projects: the Sewatec type series

The Sewatec type series is ideal for flow rates and heads smaller than those covered by Sewatec SPN.

Advantages of Sewatec:

- Volute casing pump installed in a horizontal or vertical position.

- Available in explosion-proof design with discharge flange to DIN and ANSI standards.

- Reliable, non-clogging impellers with large free passages, optimised for every type of waste water.

- Energy-saving thanks to the PumpDrive variable speed system, highly efficient KSB SuPremE® motor and optimised hydraulic system.

Learn more about the Sewatec type series

Compact and powerful: KSB’s Amarex KRT type series

Suitable for water and waste water management, industry, pumping untreated waste water containing long fibres and solid substances, fluids containing gas or air, and raw, activated and digested sludge.

Advantages of the Amarex KRT:

- Wet installation possible. This pump represents an interesting cost-effective alternative as the required footprint of a pumping station for wet-installed pumps is smaller than for dry-installed pumps.

- The selection chart covers operating points of up to 2 m³/s at heads of up to and beyond 40 m (drive ratings of over 1 MW are possible).

- Wet installation allows excess heat from the motor to be dissipated directly into the fluid handled.

- Dry installation options offer advantages in maintenance. This is possible because the KRT with jacket cooling transfers excess heat from the motor to the fluid handled via an internal cooling system.

Learn more about the Amarex KRT type series in action: