What to consider when selecting submersible motor pumps

For waste water pumping stations to be able to work at maximum efficiency, the selection of submersible motor pumps requires many aspects to be taken into account. Read on to find out more.

For waste water pumping stations to be able to work at maximum efficiency, the selection of submersible motor pumps requires many aspects to be taken into account. Read on to find out more.

The design of submersible pumps for wastewater depends on various influencing factors

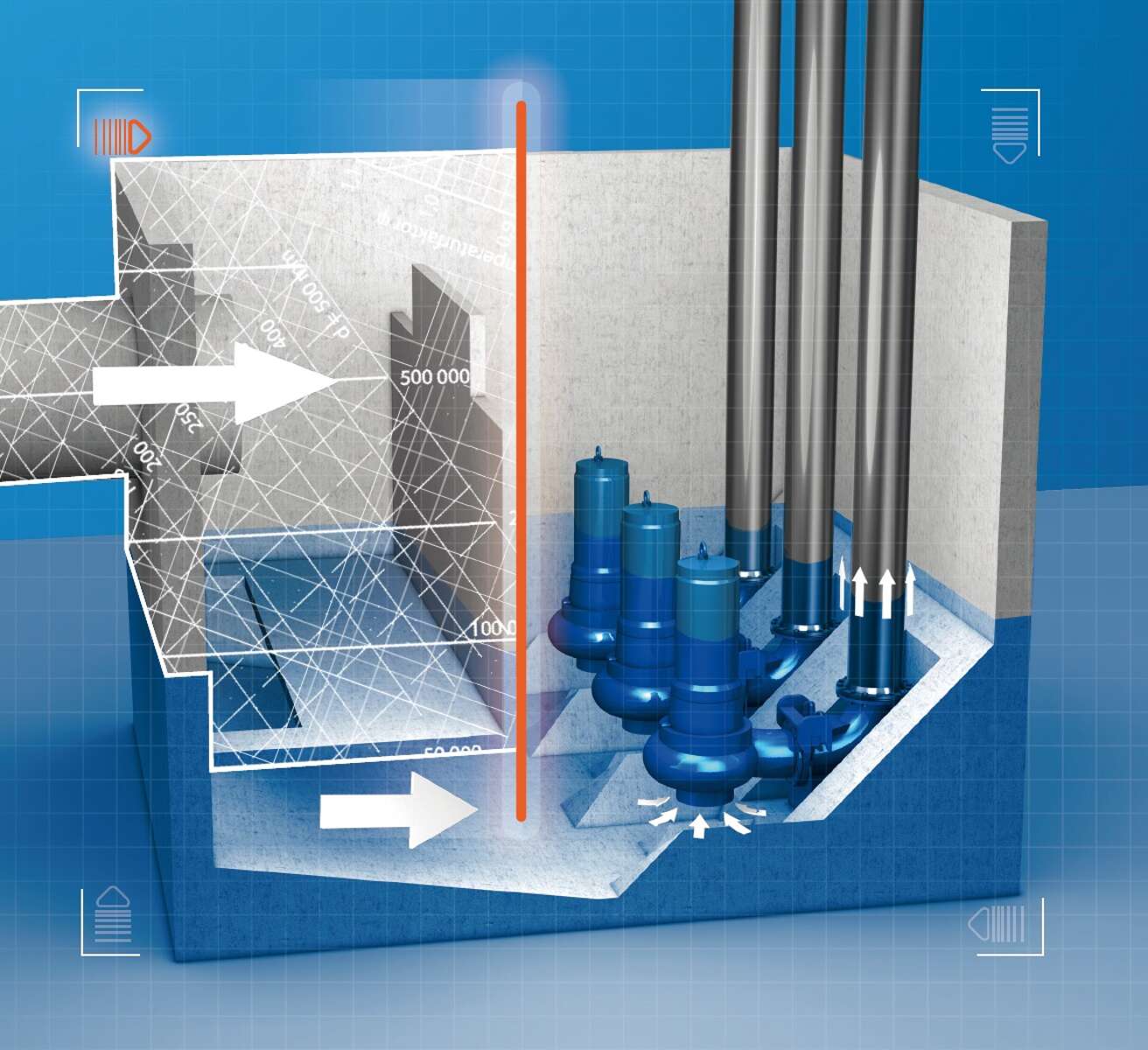

Main or intermediate pumping stations transport domestic, industrial or municipal grey water and sewage as well as stormwater. Apart from dry-installed centrifugal pumps, submersible motor pumps are also frequently employed in such pumping stations. Many system-related requirements have to be met when selecting waste water pumps, whose operation is influenced by the most diverse of factors. Piping layout, solids content and installation type, for instance, are decisive for trouble-free operation.

Where to start with the selection? What factors are to be considered to ensure a durable and smooth operation of the submersible motor pumps installed and, with that, the waste water pumping station overall?

Always look at the waste water pumping station holistically!

The first thing to consider when selecting a submersible motor pump is that it is only one component of the overall waste water system. A submersible motor pump can only be operated reliably and efficiently if its characteristics and hydraulic system are matched to the pumping station and its peripheral systems as well as to the fluid to be handled (properties and composition), the control system and the operating mode.

In its many years of experience working extensively with consultants, installers and other hands-on professionals, KSB has gained a wealth of experience when it comes to selecting submersible motor pumps for waste water pumping stations. And we would like to share it with you. Read on to find out about the main planning parameters and practical tips for the successful selection of submersible motor pumps.

Planning parameters and design data

Reaching a specific flow rate and head is the focus of choosing a submersible motor pump. The head is calculated based on the height difference of the reservoirs and on the friction losses in the piping and related components. The actual flow rate depends on a number of influences that are crucial in the selection of submersible motor pumps.

First of all, for an ideal pump selection, the intersection of pump characteristic curve and system characteristic curve should be calculated as precisely as possible. This is the optimum operating range in which the pump runs at its best hydraulic efficiency. For the calculation, the head H (in metres) has to be put into relation to the required waste water flow Q (in m3/h). The operating limits are designated by Qmin and Qmax.

Flow rate (Q)

Calculating the required flow rate, or inflow, as precisely as possible is very important for correctly determining the operating range of the submersible motor pump and dimensioning the entire waste water pumping station. This will allow the pump to operate efficiently.

Calculating the required flow rate, or inflow, as precisely as possible is very important for correctly determining the operating range of the submersible motor pump and dimensioning the entire waste water pumping station. This will allow the pump to operate efficiently.

Head (H)

The head developed by a pump is defined as the useful mechanical work transferred to the fluid handled per weight of the fluid handled, taking into account the local acceleration due to gravity. Key information required to determine the head are, for example: the height AOD (Above Ordnance Datum) of the inlet channel invert, the cut-in and cut-out points of the pumps, the terrain between the pumping station and the pumping destination, the valves, fittings and pipelines installed, their nominal sizes (DN) and resistance coefficients (ζ) as well as the discharge height AOD at the pumping destination.

The head developed by a pump is defined as the useful mechanical work transferred to the fluid handled per weight of the fluid handled, taking into account the local acceleration due to gravity. Key information required to determine the head are, for example: the height AOD (Above Ordnance Datum) of the inlet channel invert, the cut-in and cut-out points of the pumps, the terrain between the pumping station and the pumping destination, the valves, fittings and pipelines installed, their nominal sizes (DN) and resistance coefficients (ζ) as well as the discharge height AOD at the pumping destination.

NPSH

The NPSH indicates the suction characteristics of a pump. It stands for the minimum pressure in the inlet required by every pump to be able to run reliably and without cavitation. In general, a distinction has to be made between the NPSH3% (permissible cavitation influence with a 3 % drop in head) of the pump, also referred to as NPSHrequired or net positive suction head of the pump and the NSPH of the system, also referred to as NPSHavailable or net positive suction head of the system. The NPSH3% can be influenced by the submersible motor pump's impeller type and rotational speed.

The NPSH indicates the suction characteristics of a pump. It stands for the minimum pressure in the inlet required by every pump to be able to run reliably and without cavitation. In general, a distinction has to be made between the NPSH3% (permissible cavitation influence with a 3 % drop in head) of the pump, also referred to as NPSHrequired or net positive suction head of the pump and the NSPH of the system, also referred to as NPSHavailable or net positive suction head of the system. The NPSH3% can be influenced by the submersible motor pump's impeller type and rotational speed.

Power input

The power input is the mechanical power transferred from the drive to the pump shaft or coupling. The power input must not be confused with the power available at the drive, which is referred to as the drive rating or motor rating PN, indicated by the motor manufacturer on the rating plate.

The power input is the mechanical power transferred from the drive to the pump shaft or coupling. The power input must not be confused with the power available at the drive, which is referred to as the drive rating or motor rating PN, indicated by the motor manufacturer on the rating plate.

Parallel operation and reduced pump characteristic curves

In parallel operation, the total flow rate is composed of the flow rates of the individual pumps at a given head. The head of each individual pump must be reduced by the dynamic component of head losses occurring in the individual discharge line up to the collecting line. The system characteristic curve of the collecting line only contains the head losses downstream of the point where the individual lines join.

Pressure loss calculation helps determine the head

To calculate the heads actually required from a pumping system in a reproducible way, a pressure loss calculation has to be carried out. First of all, information is needed about the basic project requirements: A quantity X of waste water (in litres) has to be transported from A to B. Next, the recommended flow velocities for waste water are used to estimate the pipe cross-sections. While the minimum flow velocities for reliably transporting solids contained in the fluid have to be observed, economic considerations regarding maximum flow velocities also have to be taken into account. The resulting diameters are used to calculate the pressure losses.

The head loss (HL) for straight pipes is calculated as follows:

The head loss (HL) in valves and fittings is calculated as follows:

Practical tips

Here are some valuable tips on how to avoid typical errors or overcome challenges that may arise during selection:

- Look at the pump and system holistically.

- Select a suitable impeller type and impeller material for the fluid handled.

- Make sure the operating point is near the best efficiency point, i.e. within the optimum operating range.

- Check the minimum flow velocities in horizontal and vertical pipes.

- Consider the circumferential velocity at the outside diameter of the impeller.

- Check the minimum water level in the inlet tank to prevent air-entraining vortices.

- Take into account the frequency of starts of the submersible motor pumps.

- Calculate the reduced pump characteristic curves.

- Observe the minimum flow velocity required to open the swing check valves.

Conclusion

The selection of a suitable pump is largely determined by the specified operating conditions. The operating conditions primarily comprise data on the fluid handled (e.g. temperature, density, viscosity, dry solids content, sand content or other substances in the fluid), the expected flow rate and the required head, the suction behaviour, the speed, and the installation type of the submersible motor pump. Further information required for the selection: Size and connection values of the drives, operating modes, expected frequency of starts and influences by the system and environment (max. noise emissions, permissible vibrations, other vibrations occurring in the piping, etc).

KSB will be pleased to assist you with selecting and planning your waste water pumping station. Don’t hesitate to contact us!

Suitable products

Amarex KRT

Horizontal or vertical single-stage submersible motor pump in close-coupled design, with various next-generation impeller types, for wet or dry installation, stationary or transportable version, with energy-saving motor and models for use in potentially explosive atmospheres.

Sewatec

Volute casing pump for horizontal or vertical installation, with various next-generation impeller types, discharge flange to DIN and ANSI standards. Explosion-proof version available.