KSB delivers certified OH1 pump packages to Sonatrach’s MTBE project in Algeria|Setting a new benchmark for China–Algeria energy cooperation

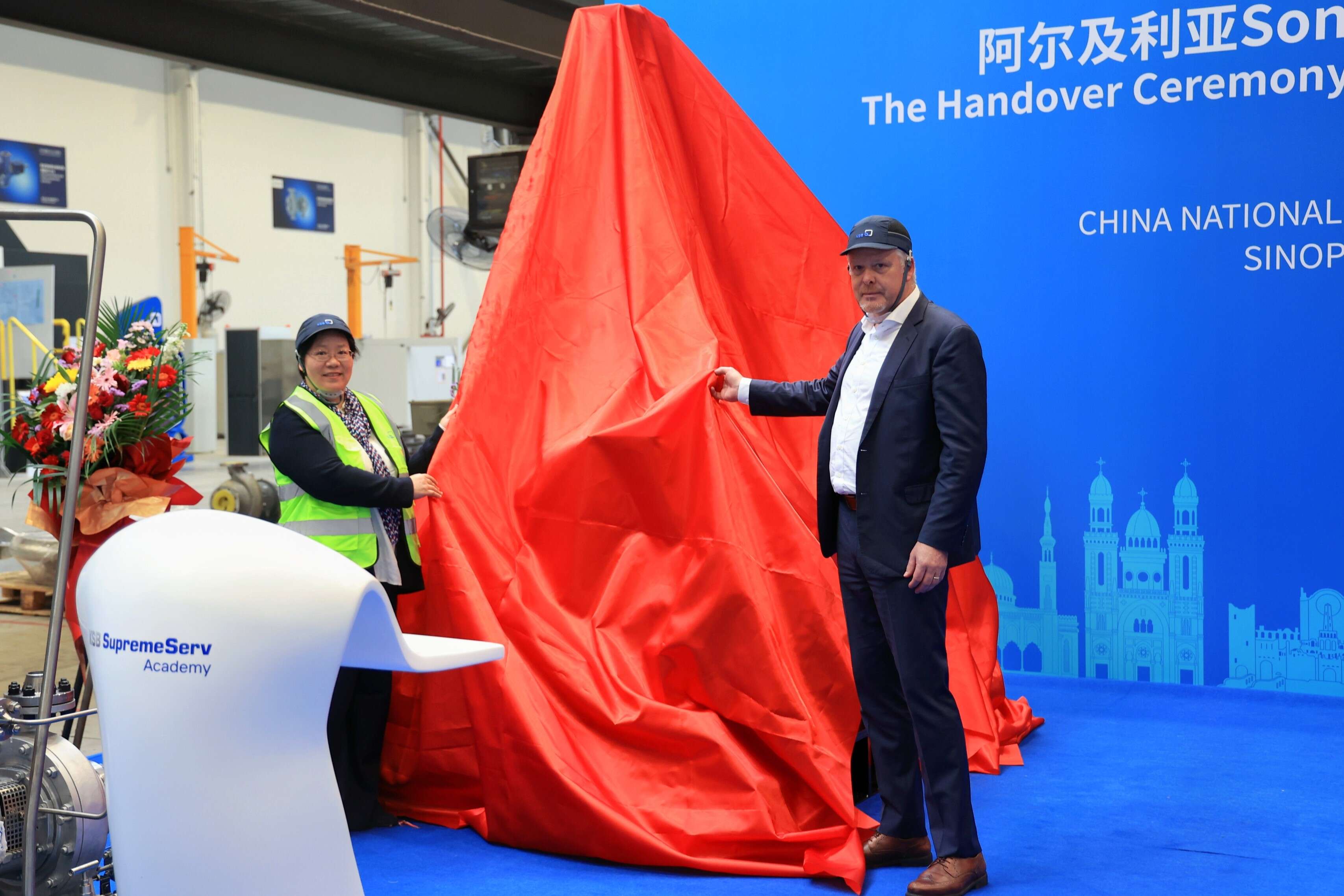

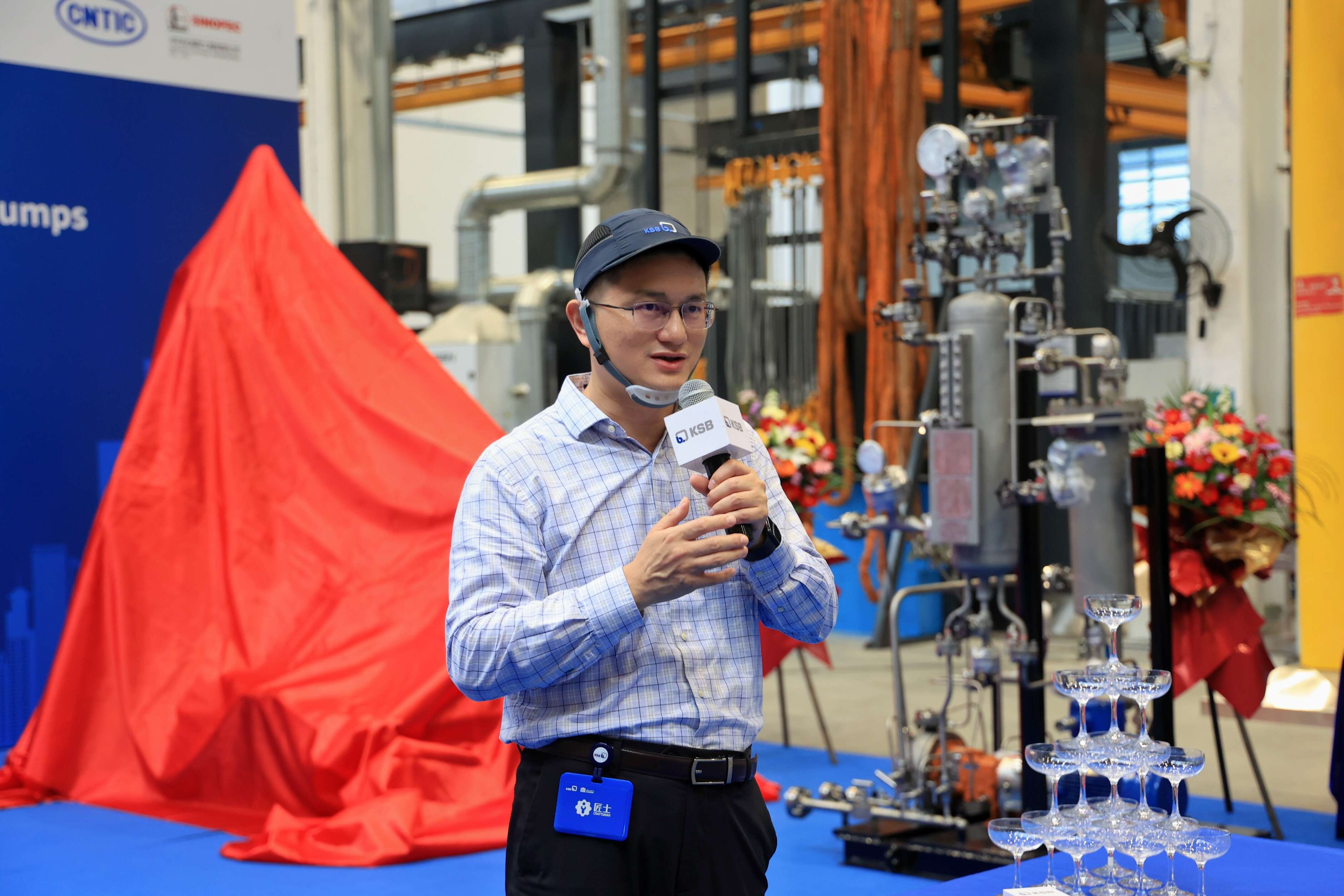

Shanghai, 23 May 2025 — KSB today marked a major milestone on Sonatrach’s MTBE project in Algeria, executed by China National Technical Import & Export Corporation (CNTIC) and Sinopec Luoyang Engineering Co. (LPEC). The first OH1 pump packages were officially handed over, signaling the project’s transition into full implementation. The ceremony was kicked off by the President KSB Petrochemicals / Chemicals, underscoring KSB’s commitment to innovation, compliance and on‑time delivery across complex international EPC programs.

As a core rotating‑equipment supplier, KSB combined its made‑in‑China capabilities with its global engineering and supply chain to overcome bilingual documentation, stringent third‑party certification and no‑deviation requirements—once again validating the company’s global technical strength.

Project at a glance: delivering a high‑complexity international EPC

International collaboration: The project integrates Sinopec’s overseas EPC execution model with Sonatrach standards and Algerian localization requirements. All technical documentation, submittals and acceptance packages were delivered in English and French to sustain cross‑border efficiency and auditability.

Zero‑compromise certification: The customer applied the French ARH certification regime with independent third‑party witnessing from design and material selection through production inspection—explicitly prohibiting technical deviations. KSB upgraded critical component materials and refined its patented coupling‑guard design, achieving a 100% pass rate across all witnessed certifications.

Key milestones:

Sep 2023: Initial proposal and technical basis established

Apr 2024: Equipment procurement contract signed

Mar 2025: First product batch shipped

23 May 2025: OH1 pump package handover ceremony; project enters full execution

May 2025: Completion of ARH certification and final deliveries

Engineering breakthroughs: how KSB removed barriers

Hydraulic model advancement: KSB’s Shanghai R&D team developed a customized scheme for the MCPK (MegaCPK) chemical pump line. Following batch validation, the solution was deployed on this project, providing a replicable upgrade path for similar pump types.

End‑to‑end program control: To satisfy Sonatrach’s zero‑deviation principle, KSB formed a cross‑functional task force spanning China, Germany and Algeria. The team enhanced design reliability and orchestrated a global supply response—prioritizing critical components across KSB’s 35 manufacturing sites and 9 foundries to secure schedule and quality.

Global network, local assurance

Five central spare‑parts hubs across four continents—including Shanghai (China), Johannesburg (South Africa) and Frankenthal (Germany)—enable:

24‑hour response for African project needs and rapid local delivery;

Localized warehousing that lowers logistics costs and emissions in line with Belt and Road “green and smart” supply chain goals;

Full lifecycle support, from installation and commissioning to predictive life assessment, delivered through KSB’s 190 service workshops worldwide.

Mutual success for China–Algeria cooperation and Sinopec’s global projects

First‑of‑its‑kind integration: The project achieved the first domestic integration of KSB MegaCPK (MCPK) pumps with steam‑turbine drive packages for export EPC delivery. By aligning German process‑pump standards with Sinopec’s EPC framework, KSB has opened a new pathway to equipment localization for Sinopec’s overseas portfolio.

A scalable benchmark: Combining international brand technology with Chinese central‑SOE EPC execution provides dual assurance—technical compliance and cost competitiveness—for “China‑based equipment” entering Africa’s high‑end energy market.

Looking ahead

The Algeria MTBE handover highlights KSB’s leadership in complex projects and the deep integration of “smart manufacturing in China” with top‑tier global standards. Building on this success, KSB will continue to deepen cooperation with CNTIC, Sinopec and other strategic partners. Anchored by 35 manufacturing sites, 9 foundries and 5 regional spare‑parts hubs, KSB stands ready to power the next wave of Belt and Road energy collaboration.