KSB SupremeServ

Always there for you

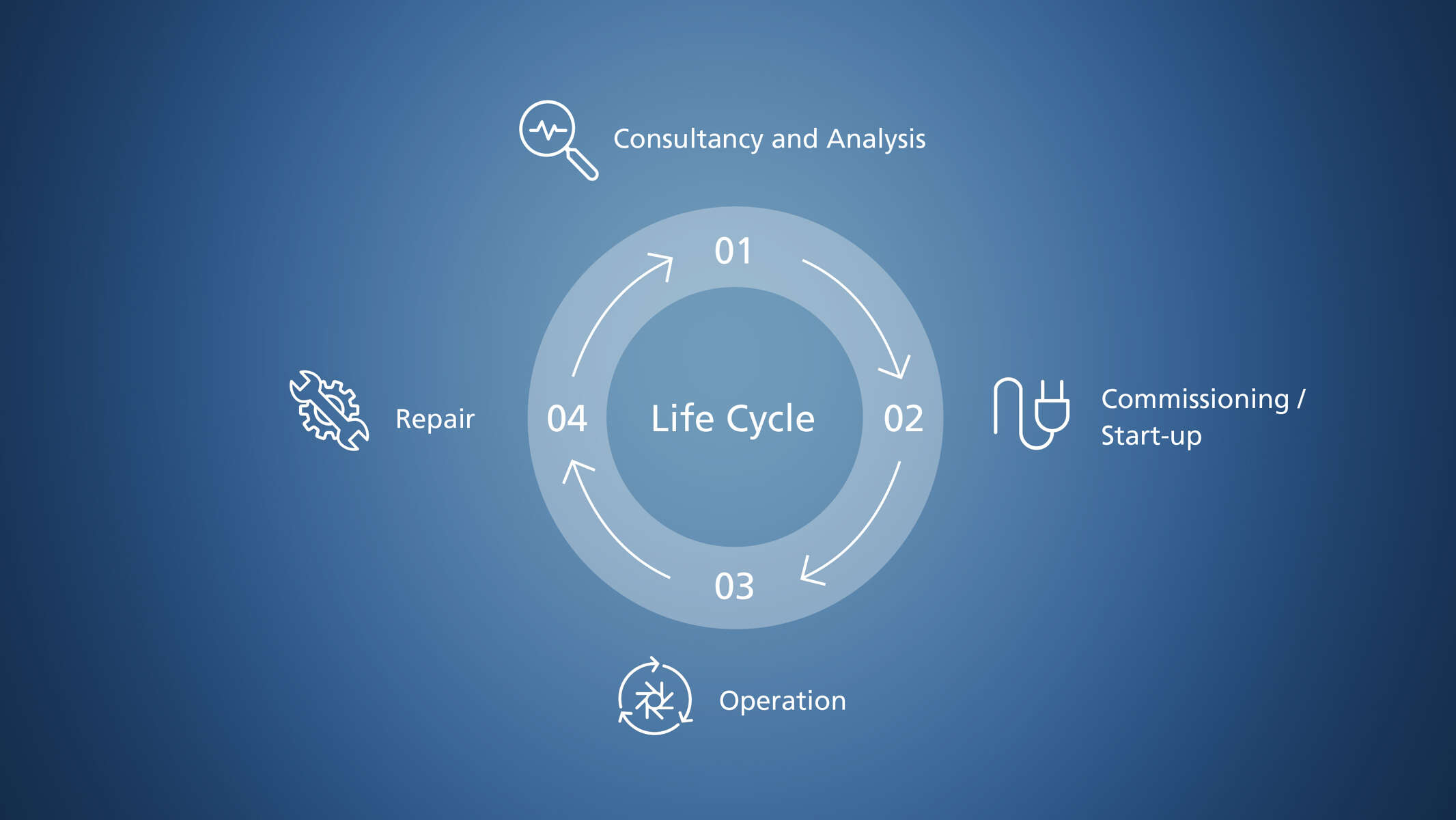

From initial consultancy, planning, installation, operation and maintenance to classic and digital service concepts: KSB is on hand to help you over the entire life cycle of your system. And this with more than 3500 specialists in over 190 service centres around the globe.

To successfully operate your system, you need more than excellent products

Benefit from the extensive KSB SupremeServ service and spare parts portfolio:

- For pumps, valves and other rotating equipment

- On-site and in our service centres

- Around the globe

- Based on 150 years of manufacturer know-how