Country, region and language selection

Europe

- Austria

- Belarus

- Belgium

- Croatia

- Czech Republic

- Denmark

- Estonia

- Finland

- France

- Germany

- Great Britain

- Hungary

- Italy

- Latvia

- Lithuania

- Netherlands

- Norway

- Poland

- Portugal

- Romania

- Russia

- Serbia

- Slovakia

- Slovenia

- Spain

- Sweden

- Switzerland

- Turkey

- Ukraine

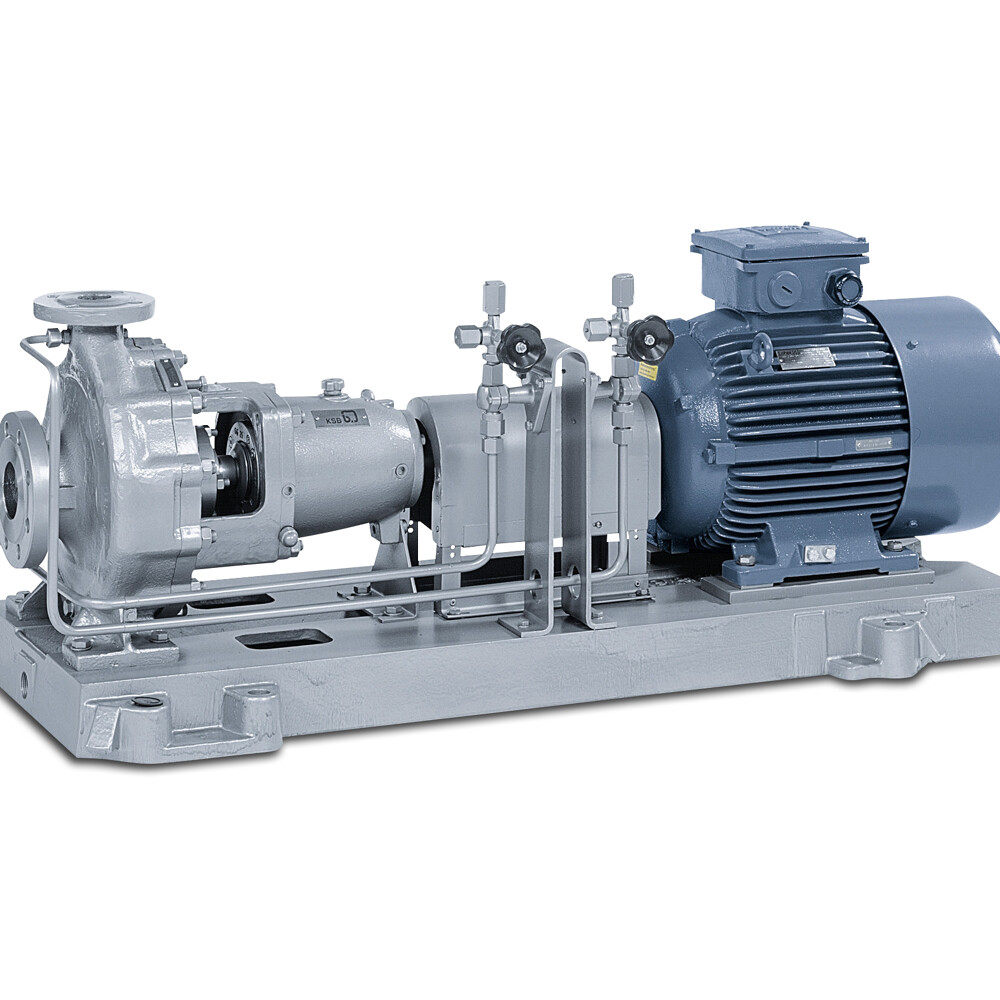

Principali applicazioni

- Pompa per il convogliamento di acqua surriscaldata, fluidi termovettori organici o sintetici in impianti a tubazioni o sistemi a serbatoi.

- Impianti di riscaldamento

- Caldaia a circolazione forzata

- Alimentazione del teleriscaldamento

Dati tecnici

- Massima portata

- 4800 m³/h

- Massima prevalenza

- 275 m

- Massima Pressione di esercizio ammessa lato pressione

- 40 bar

- Massima temperatura fluido ammessa

- 240 °C

Vantaggi

- Sistema idraulico, dati nominali e dimensioni secondo ISO 2858/EN 22858

- Lubrificazione e controllo costanti del livello dell'olio tramite il regolatore del livello dell'olio

- Tipologia di processo, in caso di smontaggio della pompa, il corpo pompa può rimanere nella tubazione

Dati tecnici

- Funzione del componente

- Convogliare

- Tipo di collegamento Ingresso

- Flangia

- Modello attuatore

- con attuatore elettrico

- Massima portata

- 4800 m³/h

- Portata minima

- 1 m³/h

- Massima prevalenza

- 275 m

- min.preval. gen.serie costr.

- 2 m

- Frequenza di rete

- 50 Hz,

60 Hz - Tensione di rete

- 400 V,

460 V - Materiale del corpo

- GX23CRMOV12-1,

EN-GJS-400-18-LT,

GP240GH+N/A216 GRADE WCB - Pressione nominale Uscita

- PN 40

- Massima Pressione di esercizio ammessa lato pressione

- 40 bar

- Comportamento di aspirazione

- ad aspirazione normale

- Massima temperatura fluido ammessa

- 240 °C

- Temperatura fluido minima ammessa

- 5 °C