Country, region and language selection

Europe

- Austria

- Belarus

- Belgium

- Croatia

- Czech Republic

- Denmark

- Estonia

- Finland

- France

- Germany

- Great Britain

- Hungary

- Italy

- Latvia

- Lithuania

- Netherlands

- Norway

- Poland

- Portugal

- Romania

- Russia

- Serbia

- Slovakia

- Slovenia

- Spain

- Sweden

- Switzerland

- Turkey

- Ukraine

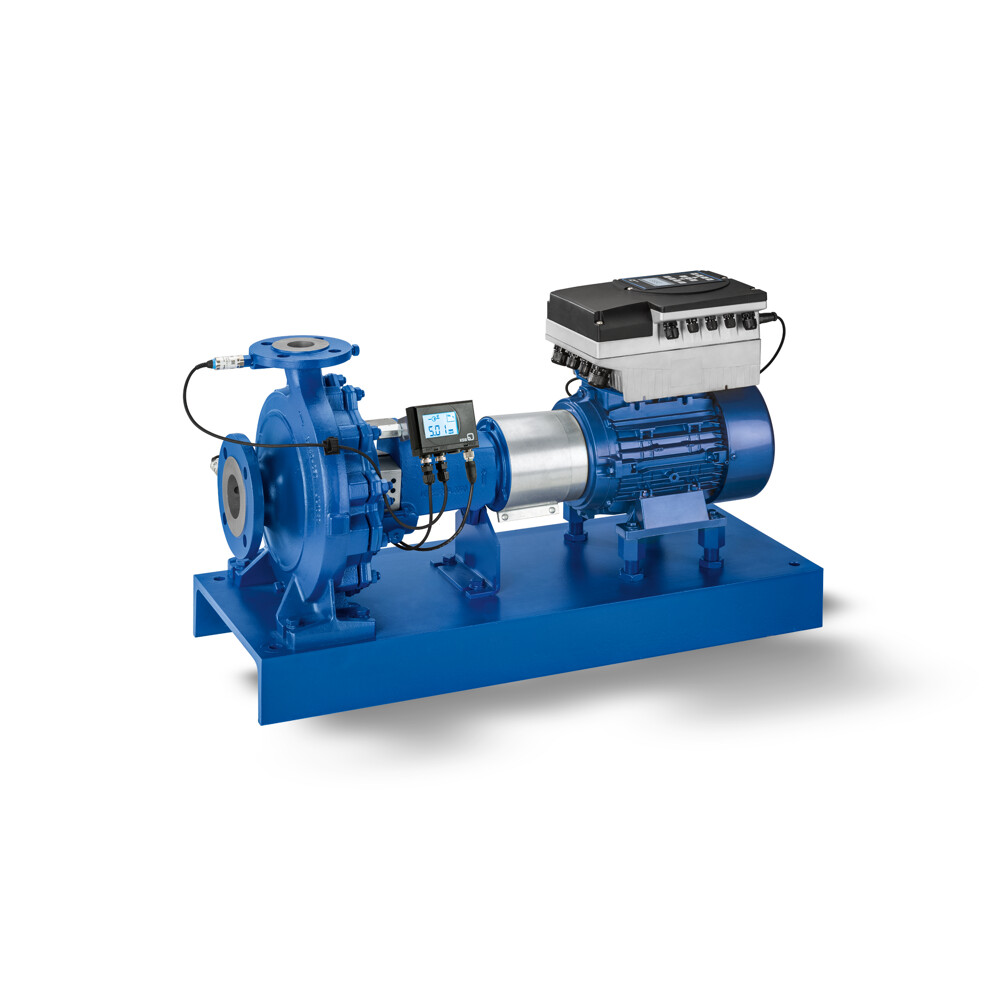

Main Applications

- Handling clean or aggressive fluids not chemically and mechanically aggressive to the pump materials.

- Water supply systems

- Cooling circuits

- Swimming pools

Technical Data

- Max. flow rate

- 1368 m3/h

- Max. head

- 160 m

- Max. allowed working pressure

- 16 bar

- Max. allowed fluid temperature

- 140 °C

Benefits

- Improved efficiency and NPSHreq by experimentally verified hydraulic design of impellers (vanes)

- Operating costs reduced by trimming the nominal impeller diameter to match the specified duty point

- Little wear, low vibration levels and excellent smooth running characteristics thanks to good suction performance and virtually cavitation-free operation across a wide operating range

Technical Data

- Function

- Pump

- Connection type

- Flange

- Drive concept

- With electric actuator,

Combustion engine - Max. flow rate

- 1368 m3/h

- Min. flow rate

- 1.5 m3/h

- Max. head

- 160 m

- Min. head

- 2 m

- Mains frequency

- 50 Hz,

60 Hz - Mains voltage

- 400 V,

460 V,

220 V,

230 V,

240 V,

380 V,

415 V,

500 V,

575 V,

660 V,

690 V - Casing material

- EN-GJL-250/A48 CL 35B,

CUSN10-C-GS/B30 C90700,

GX5CRNIMO19-11-2/A743 GRADE CF-8M,

EN-GJS-400-15/A536 GRADE 60-40-18 - Nominal pressure

- PN 16,

PN 10,

CL 150,

CL 125 - Max. allowed working pressure

- 16 bar

- Suction behaviour

- Non-self-priming

- Max. allowed fluid temperature

- 140 °C

- Min. allowed fluid temperature

- -30 °C