Armed for the flood of the century

Having agreed that Landshut must never again experience a catastrophic flood as it did in 2013, the city’s authorities launched a construction project in 2018 with the goal of protecting the Lower Bavarian city from flooding for generations to come. Particularly with regard to climate change and the resulting increase in heavy rainfall events, being adequately prepared for extreme weather in the future was a matter of urgency.

The project: A flood water pumping station for Landshut

When elevated water levels coincide with heavy rainfall, urban drainage systems have to remove huge amounts of water from the lower-lying areas of the city within minutes. However, 2013 saw these previously effective systems become overwhelmed, especially by flooding from the Isar river. The flood relief channel was filled to the brim with water, roads were flooded and parts of the industrial area were no longer passable.

The plan was to build a new pumping station for the city of Landshut specifically designed for disaster situations – to be used when all reservoirs including flood relief channels, stormwater overflow basins and storage sewers were full and the water could no longer drain away fast enough.

The customer: Stadtwerke Landshut

Landshut’s municipal utilities supply around 92,000 households with electricity, natural gas, water and district heating. Waste water and stormwater is collected and transported via a 370-kilometre sewerage network which includes combined sewers heading to the treatment plant in Landshut-Dirna, and dedicated stormwater sewers which route water directly into nearby streams and infiltration basins in deeper soil layers.

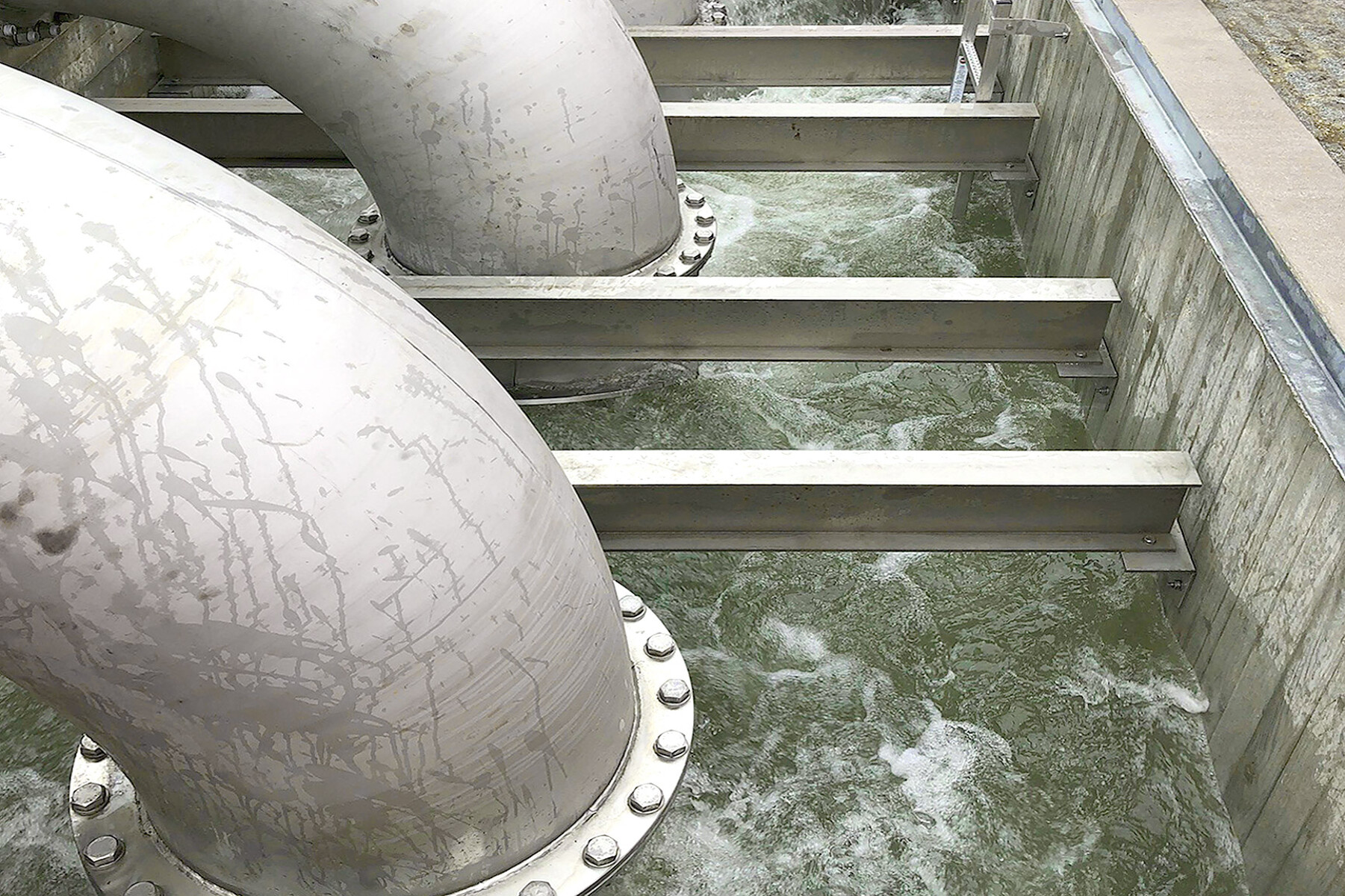

A water drainage basin, in front of it discharge tubes to the Amacan pumps

The challenge: Being prepared for disaster

Emergency situations such as excessively high water inflow within a very short time can often only be simulated in advance on computer. Many cities cannot make 100% promises when it comes to flood protection. For economic and technical reasons, their sewers are generally dimensioned for unusually heavy rainfall which might occur every few years, but not for a rainfall of the century. Landshut, however, sought to guarantee 100% safety at a reasonable investment cost. And it was clear from the start that the construction of this system must not increase sewerage charges for the connected households.

The solution: High-performance propeller pumps from KSB

In this case, consultants Lichtenecker und Spagl Ingenieure were able to draw on data provided by the flood of 2013. This meant that actual water volumes and flow patterns could be included in the planning of the new flood water pumping station, and the system could be dimensioned accordingly.

The flood water pumping station will be used when the stormwater overflow basin can no longer drain fast enough due to flooding. The excess water will then be fed through three large pipes into the underground pumping station before flowing to KSB’s Amacan high-performance propeller pumps. Two of them remain continuously operational in case of an emergency, the third providing redundancy only. When the time comes, the water can fill the reservoir below ground to a height of 3 m before it is drawn in by the two pumps and pumped from a depth of 5 m to the surface, where it can drain off in a controlled manner into the Pfettrach stream. Each KSB pump can draw in up to 1m3 of water per second.

The Amacan P submersible motor pump is tailor-made for this application: It features a doub mechanical seal in tandem arrangement to protect against fibrous materials and high-quality, wear-resistant seal face materials. It is thus designed for many years of trouble-free operation and is perfectly suited for permanent installation in the difficult-to-access discharge tube.

The entire system is designed for at least 50 years, even though all those involved hope to use it only rarely. But when the worst comes to the worst, it must start up within seconds and prove itself without compromise. KSB has made sure that this dramatic moment need not give rise to panic.

Graphical depiction of Amacan P submersible motor pumps installation and connected water outlet

Figures I Data I Facts

System: Flood water pumping station

End user: Stadtwerke Landshut

Project data:

- 3x Amacan P submersible motor pump with axial propeller

- Flow rate: up to 7000 l/s

- Head: up to 12 m

Products used

Amacan P

Wet-installed submersible motor pump for installation in discharge tubes, with axial propeller in ECB design, single-stage, single-entry. ATEX-compliant version available.